Sorry to nitpick, but "back stab" isn't correct terminology for these "Self-Contained Devices" (SCD), as they are called in the code. Back-stab refers to spring loaded push-in connectors that are limited to 14 gauge wire. Back-stab got a bad reputation back in the 70's and 80's because the retaining springs were inadequate and wires popped loose, especially if installed without adequate slack in the wiring. Since then, the stab springs have been greatly improved (at least on the better quality outlets) and UL, CSA and the NEC limit the stab to 14 gauge wire to reduce the tension on it.

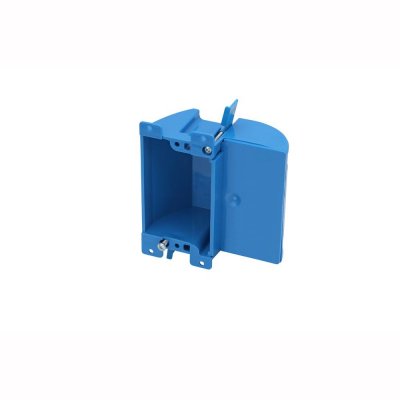

An SCD uses twin V-shaped slots for each wire and the wire is pressed in using a special tool, with the insulation still in place. The slots edges cut the insulation si it need not be removed. After the wires are in place, a back cover acts as a retainer as well as an electrical shield, so no outlet box is required. For more details, see

https://mobilehomepartsstore.com/Merchant2/documents/scd-instructions.pdf

DIY people often get frustrated with these unfamiliar devices, I think mostly because they are difficult to unwire/rewire without special tools and replacements are often not available in local store. It's popular to denigrate the SCD's, but [in my opinion] they are not any more likely to fail than a screw terminal type. Maybe even less, since screws can vibrate loose. If you've ever tried to remove a wire from an SCD slot, you know that problem ain't too likely!

I'll admit that RV manufacturers have a genius for finding cheap components that may have marginal quality/performance, so there are maybe some mediocre SCD outlets in some RVs. And the RV assembly process isn't always top shelf either.