G

Guest

Guest

Hi,

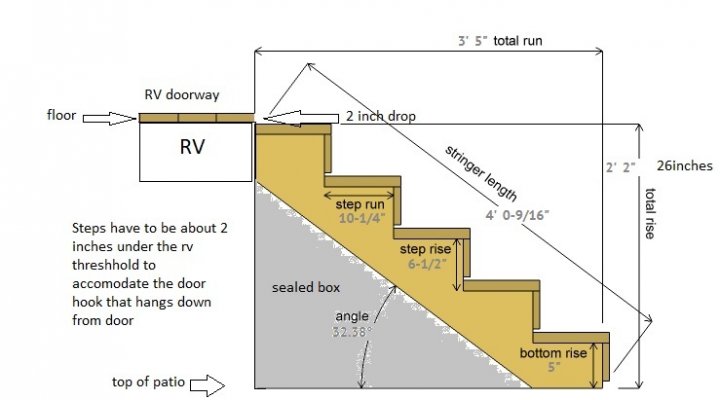

I was curious how many boards i need for this project and other stuff i might need. I have some 1/2 inch plywood already, about 3/4 of the 4x8 sheet left over. And i have tons of nails and screws. How many boards do i need. I am 300lbs so i need it to be really strong. I plan on screwing it to my wood patio and also using some 1x2 as trim around the bottom to help secure it as well.f

So i figure 2 1x2x8ft and i dont know how many 2x12x8ft ill need. Looks like the factory rv steps are about 26 inches wide so i guess these will be about the same, or maybe i better go 30 just to have some extra space.

I was curious how many boards i need for this project and other stuff i might need. I have some 1/2 inch plywood already, about 3/4 of the 4x8 sheet left over. And i have tons of nails and screws. How many boards do i need. I am 300lbs so i need it to be really strong. I plan on screwing it to my wood patio and also using some 1x2 as trim around the bottom to help secure it as well.f

So i figure 2 1x2x8ft and i dont know how many 2x12x8ft ill need. Looks like the factory rv steps are about 26 inches wide so i guess these will be about the same, or maybe i better go 30 just to have some extra space.