B

Boat Addict

Guest

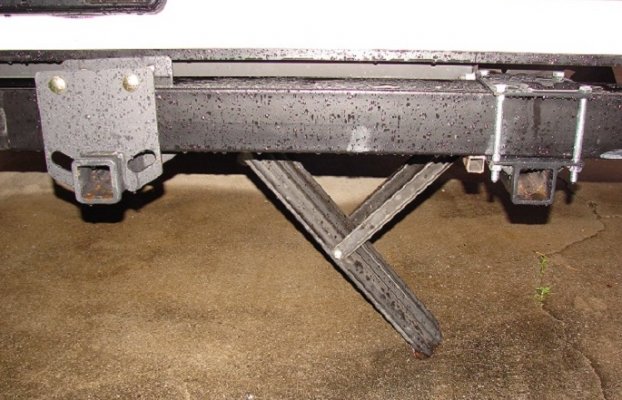

I am just curious about how much have any of you guys put on a 2 " inch hitch receiver setup mounted to the sewer tube and carried across the road with success? I have a decent quality add on receiver that many use for a rack and have actually reinforced the brackets that's bolted to the main frame and under the entire tube out to the outside so that some of the load cam be transferred from the tube.