SargeW

Site Team

And I am glad I did. I went into Freightliner Tolleson and talked to Kirk, a really good guy. I explained the pulling and what what it felt like behind the wheel. When I first talked to him on the phone and set it up, he quoted me a price of about $340, plus $75 if the front tires need to be rotated. When I arrived Kirk looked at my rig and noted that I have a straight front axle as opposed to an IFS suspension. WOO HOO, that saved me about $80 bucks right off the top, as the straight axle is easier to align, and no rotation was needed.

When I picked it up, Kirk gave me a spec sheet that indicated that the alignment was out a good bit, and one side required a shim to put everything back in order. Interesting though, that to my recollection I have never hit anything that would cause a dramatic shift in the alignment. However, over a period of time the alignment was out considerably. Kirk did note however that there was NO evidence of unusual wear on either of the front tires ;D

One small gripe about the resulting repair. When I got back inside and was heading West on the I10 outside of Phoenix there was a strong crosswind, so I really didn't get to check much about the new feel of the alignment as I was just trying to keep the rig between the lines. Later when I got farther down the road into California and the winds subsided, I noted that the steering wheel was off center quite a bit, kinda like driving down the road making a left turn. Checking the repair order, I did note that Kirk had written on the repair order "center the steering wheel".

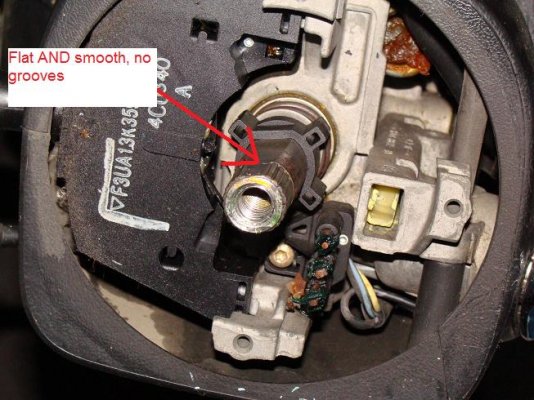

I called him up and he indicated that sometimes the tech will pull the steering wheel, but the alignment splines on the steering shaft prevent the steering wheel from being close enough to center. He offered to take it back and readjust it, but already being in Ca, that was not much of an option. Instead I obtained the size of the jamb nut from him and went to the local Napa store and picked up an 1 1/4 socket and a steering wheel puller for about $20. I removed the steering wheel pad (one screw under the pad removed from the bottom) lifted off the pad and pulled the nut and then the steering wheel off. I moved the wheel back to the right one spline on the shaft and put it all back together.

The next leg of the journey to So. Cal was smooth, and the steering wheel was almost perfect. All in all I was VERY happy I decided to have the alignment checked. BTW, I never did have the alignment checked after I loaded the rig for fulltiming 9 months ago, so I was due anyway (as is recommended in the Freightliner manual). It's a good idea if your rig is not behaving as it once was, that a check of the alignment might save some real big bucks down the road in the form of new tires.

Sarge

When I picked it up, Kirk gave me a spec sheet that indicated that the alignment was out a good bit, and one side required a shim to put everything back in order. Interesting though, that to my recollection I have never hit anything that would cause a dramatic shift in the alignment. However, over a period of time the alignment was out considerably. Kirk did note however that there was NO evidence of unusual wear on either of the front tires ;D

One small gripe about the resulting repair. When I got back inside and was heading West on the I10 outside of Phoenix there was a strong crosswind, so I really didn't get to check much about the new feel of the alignment as I was just trying to keep the rig between the lines. Later when I got farther down the road into California and the winds subsided, I noted that the steering wheel was off center quite a bit, kinda like driving down the road making a left turn. Checking the repair order, I did note that Kirk had written on the repair order "center the steering wheel".

I called him up and he indicated that sometimes the tech will pull the steering wheel, but the alignment splines on the steering shaft prevent the steering wheel from being close enough to center. He offered to take it back and readjust it, but already being in Ca, that was not much of an option. Instead I obtained the size of the jamb nut from him and went to the local Napa store and picked up an 1 1/4 socket and a steering wheel puller for about $20. I removed the steering wheel pad (one screw under the pad removed from the bottom) lifted off the pad and pulled the nut and then the steering wheel off. I moved the wheel back to the right one spline on the shaft and put it all back together.

The next leg of the journey to So. Cal was smooth, and the steering wheel was almost perfect. All in all I was VERY happy I decided to have the alignment checked. BTW, I never did have the alignment checked after I loaded the rig for fulltiming 9 months ago, so I was due anyway (as is recommended in the Freightliner manual). It's a good idea if your rig is not behaving as it once was, that a check of the alignment might save some real big bucks down the road in the form of new tires.

Sarge