Pubtym

Well-known member

I have a 2006 Itasca Suncruiser Model 35 U. I, as well as others, hear and read posted horror stories of repair bills and operator challenges to keep four on the ground...or four stored. We all can agree...HWH has a fine design for the leveler jack system...but this discussion thread provides my research into some of their key system parts...and their documented high failute rates. Basically, a system is only as good as the quality and reliability of its parts. If alternative higher quality parts or part ideas exist, I try to provide them to you...

Before I get into specific parts..I need to provide some background information so we can all be on the same page..for considering specific issues with each part.

1. Industry Manufacturing Standards.The IP Code (or International Protection Rating[1], sometimes also interpreted as Ingress Protection Rating) consists of the letters IP followed by two digits and an optional letter. As defined in international standard IEC 60529, it classifies the degrees of protection provided against the intrusion of solid objects (including body parts like hands and fingers), dust, accidental contact, and water in electrical enclosures.[2] The standard aims to provide users more detailed information than vague marketing terms such as "waterproof". Let's focus on the first and second digets of the code..with special emphasis on the second didget.

http://en.wikipedia.org/wiki/IP_Code

2. HWH Information Bulletin, Jan 10, 2006.

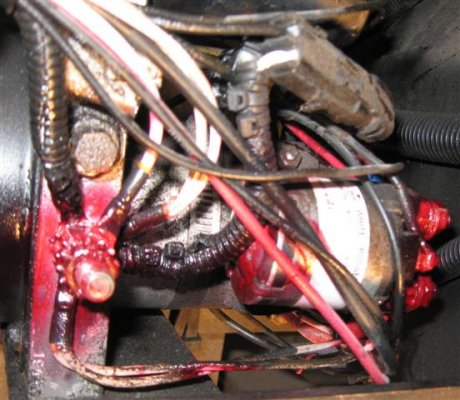

"Due to extreme weather conditions, exposed electrical connections can become corroded and deteriorated to the point of causing system failure in as little as one month of operation. On all vehicles, especially where exposure to road salts and deicing chemicals is common, all electrical connections should be protected from these conditions. Crimped and soldered connections should be protected with shrink tube. Ring terminal connections such as pump relay connections and frame ground connections should be thoroughly coated to provide protection."

http://www.hwhcorp.com/mi9554.pdf

3.The following is a quote from Drierite Website:

"Adverse Effects of Moisture"

"Water and water vapor probably cause more damage than any other contaminant, either by direct attack or by indirect means. Dampness can promote the growth of mildew or fungus. Water molecules on the surface of metals can cause rust, tarnish or corrosion. Water vapor in the atmosphere can promote chemical reactions which will corrode or destroy the material that comes in contact with the products of reaction. While the insides of a compartment or container and its contents may feel dry to the touch, a considerable amount of water may be adsorbed on the surface or in the pores of them. Changes in temperature can desorb the water and condense it into droplets causing water spots, localized corrosion or other deterioration. "

[edit]Added link to drierite.com[/edit]

More on specific HWH parts...and the relationship of the three paragraphs above?.....more to follow

Before I get into specific parts..I need to provide some background information so we can all be on the same page..for considering specific issues with each part.

1. Industry Manufacturing Standards.The IP Code (or International Protection Rating[1], sometimes also interpreted as Ingress Protection Rating) consists of the letters IP followed by two digits and an optional letter. As defined in international standard IEC 60529, it classifies the degrees of protection provided against the intrusion of solid objects (including body parts like hands and fingers), dust, accidental contact, and water in electrical enclosures.[2] The standard aims to provide users more detailed information than vague marketing terms such as "waterproof". Let's focus on the first and second digets of the code..with special emphasis on the second didget.

http://en.wikipedia.org/wiki/IP_Code

2. HWH Information Bulletin, Jan 10, 2006.

"Due to extreme weather conditions, exposed electrical connections can become corroded and deteriorated to the point of causing system failure in as little as one month of operation. On all vehicles, especially where exposure to road salts and deicing chemicals is common, all electrical connections should be protected from these conditions. Crimped and soldered connections should be protected with shrink tube. Ring terminal connections such as pump relay connections and frame ground connections should be thoroughly coated to provide protection."

http://www.hwhcorp.com/mi9554.pdf

3.The following is a quote from Drierite Website:

"Adverse Effects of Moisture"

"Water and water vapor probably cause more damage than any other contaminant, either by direct attack or by indirect means. Dampness can promote the growth of mildew or fungus. Water molecules on the surface of metals can cause rust, tarnish or corrosion. Water vapor in the atmosphere can promote chemical reactions which will corrode or destroy the material that comes in contact with the products of reaction. While the insides of a compartment or container and its contents may feel dry to the touch, a considerable amount of water may be adsorbed on the surface or in the pores of them. Changes in temperature can desorb the water and condense it into droplets causing water spots, localized corrosion or other deterioration. "

[edit]Added link to drierite.com[/edit]

More on specific HWH parts...and the relationship of the three paragraphs above?.....more to follow