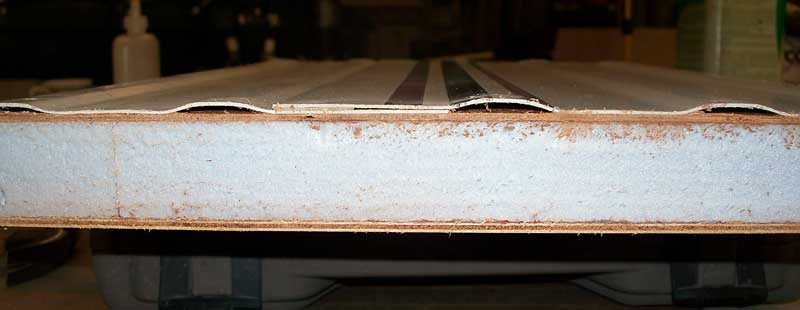

The repair can be made with EPOXY RESIN (not Polyester). The problem is one of access. If you can get the epoxy resin in the area by removing a window or outside access door or louver, then the problem is not too difficult. If not then things get a bit tougher.

Epoxy resin is a thick liquid, so will probably need to be thinned. Epoxy resin will not affect the foam board, but I don't know the effects of the thinner(s) on the foam board. Some testing may be required. If the repair is between the plywood and the fiberglass, then this is probably not a consideration. Thinning instructions can be found here:

http://www.ehow.com/how_5868793_reduce-fiberglass.html

Possible fixes:

1. If you can get to the area from the inside of the coach (inside a cabinet perhaps?), then a hole saw may give you enough of an opening to get the resin into the area. With a hole saw, saw a hole through the interior 1/8" panel, then remove the pilot drill and continue through to the void that needs gluing......being very careful not to go through the outside fiberglass. If the area to be re-glued is very large, you may need more than one hole. Remove the plug(s) and save it. Pour thinned resin into the void using funnel made of metal or cardboard or whatever, working (push and release) the fiberglass panel outside to spread the resin around. Shore up the loose area to hold the fiberglass tight until the resin hardens. Using foam and panel cement, glue the plug(s) back in.

2. A similar approach to fix 1 is to drill a series of smaller holes from the inside to the void and using a glue syringe, squirt the thinned resin into the void through the series of holes. Again, shoring up the side until the resin hardens. Caulk the holes that were drilled inside the cabinets.

3. If there isn't a way to access from the inside, then perhaps a series of very small holes outside in the fiberglass layer, just large enough for a veterinary hypodermic syringe with thinned resin can be used to get the resin inside the void........I don't know if the resin can be thinned this much, so some experimenting is in order. Epoxy glue can be used to fill the very small holes.

I'd go from inside if at all possible.