John Canfield

Site Team

-->from my thread at Rubicon Owners Forum with some edits<--

I was amazed to find out the RubiCrawler is a very popular upgrade with the FMCA 4-Wheeler crowd!

From the Advance Adapters website (they make the Atlas transfer case):

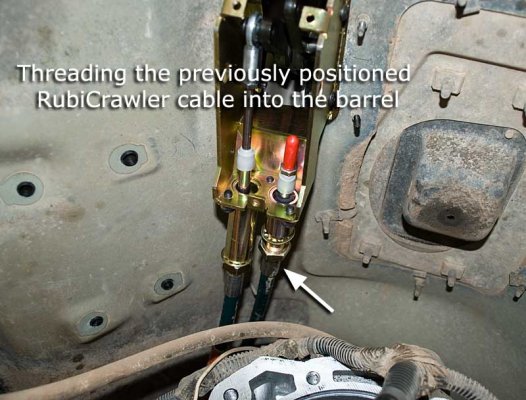

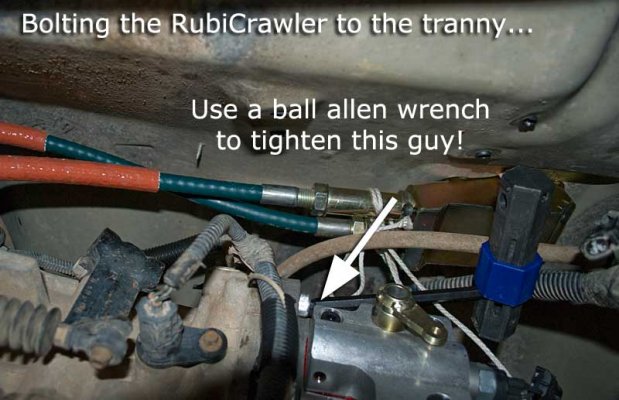

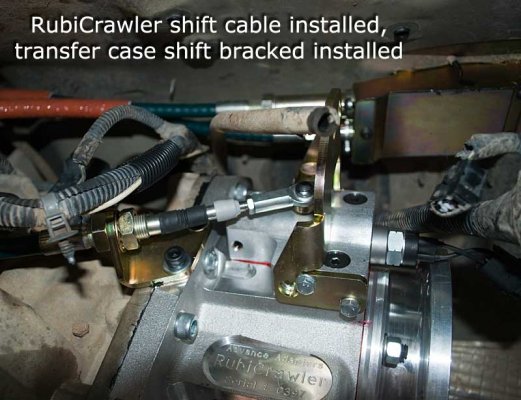

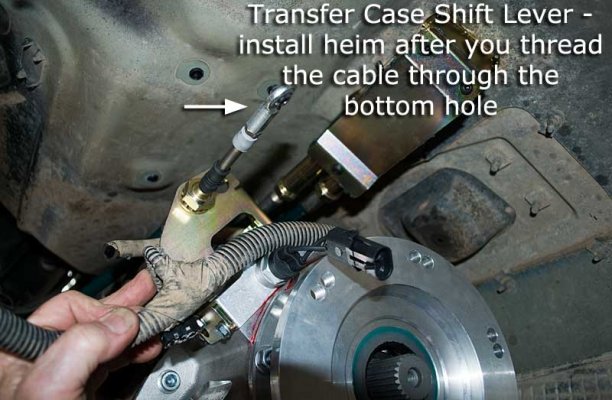

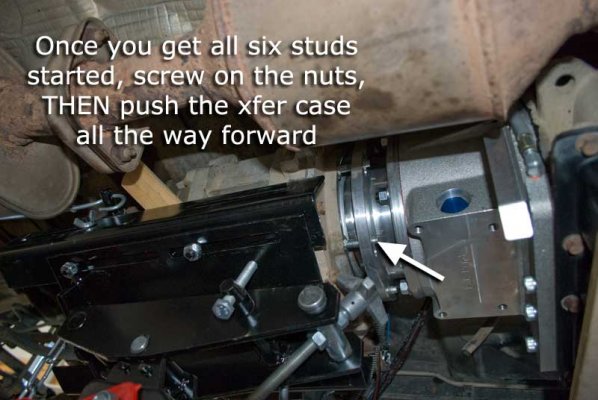

"This reduction unit replaces the stock 42RLE tailhousing with a 6 gear planetary reduction box featuring a 2.72 low range. This is a true, bolt-in doubler that couples to the stock Jeep transfer case or an existing Atlas transfer case.

Features: The RubiCrawler increases your available gear ratios. This allows you to choose the appropriate gear, depending on the terrain in which you?re wheeling. Proper gear choice will allow you more control of the vehicle. Ultimately, this contributes to a fun, and safe, offroading experience, even in extreme environments."

I wanted one of these when I realized my 4.88 gears, 35" tires did not permit very slow controlled speed rock crawling. Every time I have a epiphany, it winds up being very expensive . An Atlas transfer case replacement would have been the ideal (four vs. two transfer case gear reductions) but it would have been twice as expensive ($4k vs. $2K.)

. An Atlas transfer case replacement would have been the ideal (four vs. two transfer case gear reductions) but it would have been twice as expensive ($4k vs. $2K.)

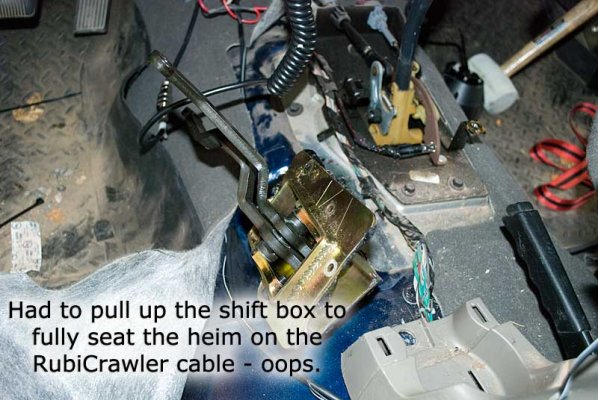

One unmentioned upgrade necessary for the RubiCrawler is upgraded axles - I already upgraded the fronts but along with the RubiCrawler install I also upgraded the rear axles to Ten Factory chrome-moly. Upgraded axles are necessary due to the extreme torque when the RubiCrawler is engaged and you are in 4-Low (10.88:1.)

I was amazed to find out the RubiCrawler is a very popular upgrade with the FMCA 4-Wheeler crowd!

From the Advance Adapters website (they make the Atlas transfer case):

"This reduction unit replaces the stock 42RLE tailhousing with a 6 gear planetary reduction box featuring a 2.72 low range. This is a true, bolt-in doubler that couples to the stock Jeep transfer case or an existing Atlas transfer case.

Features: The RubiCrawler increases your available gear ratios. This allows you to choose the appropriate gear, depending on the terrain in which you?re wheeling. Proper gear choice will allow you more control of the vehicle. Ultimately, this contributes to a fun, and safe, offroading experience, even in extreme environments."

I wanted one of these when I realized my 4.88 gears, 35" tires did not permit very slow controlled speed rock crawling. Every time I have a epiphany, it winds up being very expensive

One unmentioned upgrade necessary for the RubiCrawler is upgraded axles - I already upgraded the fronts but along with the RubiCrawler install I also upgraded the rear axles to Ten Factory chrome-moly. Upgraded axles are necessary due to the extreme torque when the RubiCrawler is engaged and you are in 4-Low (10.88:1.)