Charlie 5320

Well-known member

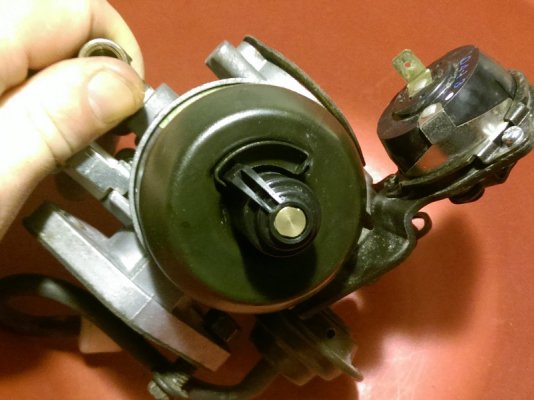

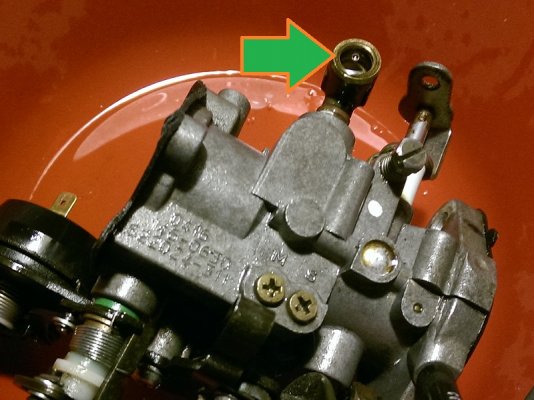

You are going to have to remove and take the carb apart to clean it or buy a new one. Take it apart and clean it, what have you got to lose? You need a can of carb cleaner and compressed air to clean out the small passages. You can get the carb cleaner at any parts store or Walmart. I use Walmart brand .