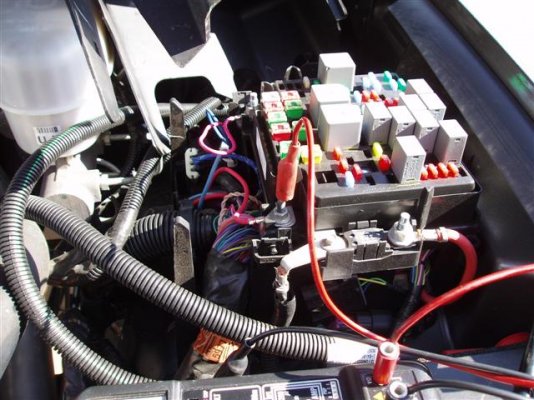

Update on the 600W sine wave inverter. Install done except for running the 120VAC back to the bedroom. Test results were good. With no load, frequency was 61Hz, scope signal was very clean except for a slight 'bubble' of about 6 volts for 23ms. on both the upslope of the positive side of zero, and the downslope on the negative side of zero. I estimate this distortion to be less than 3%. No sign of overshoot or ringing anywhere! 250W resistive load looked the same. Ran a 780W universal motor (vacuum cleaner) for about 10 minutes with no sign of overload or overheat. Heck, the cooling fan didn't even come on (the case is all heatsink with the exception of the bottom cover, which is just sheet metal). Waveform showed hash on both positive and negative slopes, but running on shore power showed the same hash. That was to be expected. Running under load, the frequency locked on at 60Hz. Conclusion: Quite frankly, I didn't expect to see such a clean and well controlled waveform. The continuous running over the rated 600W continuous rating without a hitch was also a nice surprise. All in all, I'm pleased with this unit. Whether it holds up in the long run is yet to be seen, but an inspection of the inner workings (motherboard; if you will) showed it to be well designed and built - good component placement, reflow soldering done cleanly and with no sharp wire ends, no sign of hand-wired rework or mod's, solder side had conformal coating. The only problem I had was with the supplied terminal ends for the primary power. Sized for #2 AWG, the flat end that was to be inserted into the screw terminals was slightly too wide, and required getting out the trusty old Dremel tool to take a little bit off of the sides. No big deal.

Any questions?