zmotorsports

Well-known member

I thought I had posted my residential refrigerator installation last year when I completed the job but I guess I forgot. I figured I would post up my Samsung RF18 refrigerator installation just in case anyone has a similar coach they are contemplating the modification.

After having this refrigerator installed for several trips and months now, I am glad I did it and would never own another absorption refrigerator, period. So much more room and I would bet less current draw than the old Norcold RLIM1200 on electric because I don't think with the electric element it ever turned off in warm weather. Having nice frozen ice cream and a large enough space to pack for a week is a HUGE benefit. Traveling down the road it performs flawlessly on my MSW inverter although I am contemplating upgrading my converter in the near future. Mainly to get a few more amps of charging capacity, not that it is having any issues running this refrigerator.

Big thanks to Terry Brewer for talking me over the edge on this last summer in TX. I was waffling on it as our Norcold at the time was operating just fine. It wasn't until the trip after that it started to make me nervous as it was not performing up to its capacity and I figured I would swap it out on my time frame before it gave me a time frame that was not conducive to our travel plans.

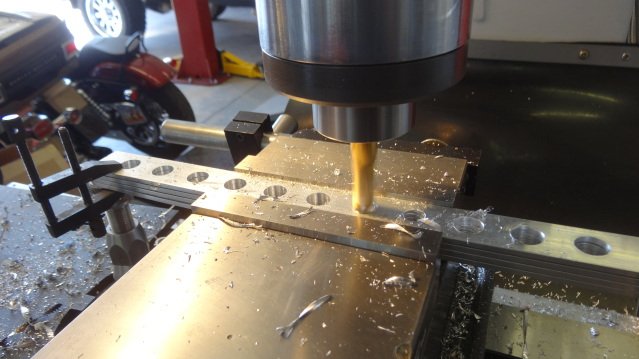

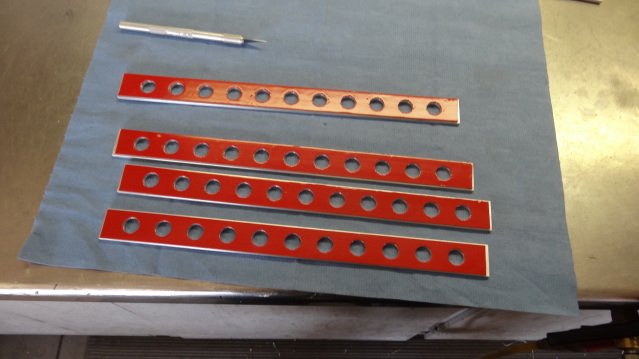

Let me preface by saying I am NOT a carpenter. I can weld/fabricate/machine just fine but working with wood is not something I excel at nor even like to do. Wood in my shop is NOT welcome and I think it knows it. That said, this is what I came up with using my very limited carpentry skills.

That said, this is what I came up with using my very limited carpentry skills.

First picture is of the OEM Norcold RLIM1200 four-door absorption refrigerator.

Second picture is with the doors and hinges off to get it out the doorway.

Third picture is with it old Norcold out and on the cart ready to remove from the coach.

Fourth picture is what is left of the opening after removal.

I was pleasantly surprised as I have seen on other threads/forums where there have been charred markings on the interior of the opening from where the original Norcold had gotten so hot that it started to char the wood. Thankfully ours was still in pristine condition.

Stay tuned...

Mike.

After having this refrigerator installed for several trips and months now, I am glad I did it and would never own another absorption refrigerator, period. So much more room and I would bet less current draw than the old Norcold RLIM1200 on electric because I don't think with the electric element it ever turned off in warm weather. Having nice frozen ice cream and a large enough space to pack for a week is a HUGE benefit. Traveling down the road it performs flawlessly on my MSW inverter although I am contemplating upgrading my converter in the near future. Mainly to get a few more amps of charging capacity, not that it is having any issues running this refrigerator.

Big thanks to Terry Brewer for talking me over the edge on this last summer in TX. I was waffling on it as our Norcold at the time was operating just fine. It wasn't until the trip after that it started to make me nervous as it was not performing up to its capacity and I figured I would swap it out on my time frame before it gave me a time frame that was not conducive to our travel plans.

Let me preface by saying I am NOT a carpenter. I can weld/fabricate/machine just fine but working with wood is not something I excel at nor even like to do. Wood in my shop is NOT welcome and I think it knows it.

First picture is of the OEM Norcold RLIM1200 four-door absorption refrigerator.

Second picture is with the doors and hinges off to get it out the doorway.

Third picture is with it old Norcold out and on the cart ready to remove from the coach.

Fourth picture is what is left of the opening after removal.

I was pleasantly surprised as I have seen on other threads/forums where there have been charred markings on the interior of the opening from where the original Norcold had gotten so hot that it started to char the wood. Thankfully ours was still in pristine condition.

Stay tuned...

Mike.