Hello everyone, we just finished up our first "big" trip to us. We went to Boston for a week and everything went great. I did nick the rim of the TT while trying to pull into the Basketball Hall of Fame. This sure is different from our pop up and I'm still trying to figure everything out. Once home and cleaned it up I found a loose self tapping bolt that hold the A frame up for the chains. This bolt looked like an odd ball compared to the others ones, so I can only assume that the dealer stripped it out during installation. It looks like they get torqued to 50 lbs. I was wondering if anyone else had this happen to them and what corrective action was used to make everyone safe again. We leave in 2 weeks for a trip and need this fixed. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reese duel cam stripped bolt

- Thread starter Camben

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Rene T

Site Team

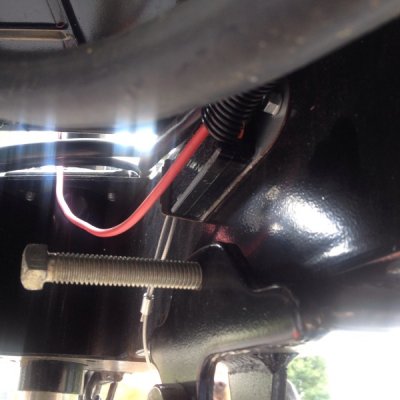

Not sure exactly what you mean when you say "I found a loose self tapping bolt that hold the A frame up for the chains". Can you show a picture?

That whole idea or using self-tapping screws is rather poor. I'm only guessing as to what your setup looks like. If the hole is stripped (enlarged), see if you can get a bolt in place from the backside. You might be able to fasten the bolt to a long stick and place it that way. If you can't keep the bolt from turning, a piece of steel welded to the nut would limit its movement.

A link to the manufactures instructions might help us to come up with other ideas.

A link to the manufactures instructions might help us to come up with other ideas.

Below are the links for the Strait Line hitch, and the next is the Dual Cam part.

http://www.hitchpro.net/application/support/instructions/n66074.pdf

http://www.reeseprod.com/content/downloads/installation/N26002.pdf

The self tapper being referred to by the OP is on sheet 10 of the second link. It's only used on Jayco's with a bottom mount coupler. It should be torqued to 50 lb/ft. If the frame is stripped, The only ways I can think of to repair is use a larger bolt, or weld up hole and redrill.

http://www.hitchpro.net/application/support/instructions/n66074.pdf

http://www.reeseprod.com/content/downloads/installation/N26002.pdf

The self tapper being referred to by the OP is on sheet 10 of the second link. It's only used on Jayco's with a bottom mount coupler. It should be torqued to 50 lb/ft. If the frame is stripped, The only ways I can think of to repair is use a larger bolt, or weld up hole and redrill.

Rene T

Site Team

Rickf1985 said:That would only be to keep the bracket in position, it is not a load bearing bolt. I see no reason why you could not drill the frame at the lower holes and put new bolts in there.

I agree. Also, if the snap up bracket gas the locking bolt on the other side of the frame. That should also just hold it on place. I don't know what the self tapping bolt would do. It doesn't add and strength to the bracket.

Rene T

Site Team

WHOA! I just saw your pictures. You should have posted them at the end of this thread then we would have seen them.

That bolt is a structural fastener. Is your frame a box beam frame or is it a channel iron frame? Myself, I would not go to a bigger self tapping bolt. The threads will only be coarser and you'll have less grip. If it was me, I would drill the hole right through the frame and use a grade 8 bolt with a self locking nut on the opposite side. Only drill out the hole to the minimum diameter necessary so you can get the next size bolt in it.

That bolt is a structural fastener. Is your frame a box beam frame or is it a channel iron frame? Myself, I would not go to a bigger self tapping bolt. The threads will only be coarser and you'll have less grip. If it was me, I would drill the hole right through the frame and use a grade 8 bolt with a self locking nut on the opposite side. Only drill out the hole to the minimum diameter necessary so you can get the next size bolt in it.

Rene T

Site Team

I just made a change to my post above.

That's not the bolt I thought you were talking about. I thought you were talking about the snap-up brackets.

http://www.reeseprod.com/content/downloads/installation/N26002.pdf

I posted the link for the Dual Cam again, look at page 5. If the dealer put self tappers to hold that bracket on, they did it wrong. There are instructions for installing and using a rivet nut for use on a tube frame. If you have a "C" channel frame, you can just through-bolt the bracket like on page 6. If you have a tube frame and use the rivet nuts, torque is 75 lb/ft, if through-bolted and using nuts and washers, the torque is 85 lb/ft. I agree with Rene, this is not the place for trying to use a larger self tapper. I would print out a copy of the instructions and take them to the dealer, demanding they fix BOTH brackets correctly. I recommend you go through the whole set-up that the dealer did, because they probably made more installation mistakes and don't have the hitch adjusted properly either.

Nomadb1 did a very good write up on the Reese Dual cam and contributed it to the library.

http://www.rvforum.net/joomla/index.php?option=com_content&view=article&id=517:reese-dual-cam-setup&catid=26&Itemid=132

You may find it very useful.

http://www.reeseprod.com/content/downloads/installation/N26002.pdf

I posted the link for the Dual Cam again, look at page 5. If the dealer put self tappers to hold that bracket on, they did it wrong. There are instructions for installing and using a rivet nut for use on a tube frame. If you have a "C" channel frame, you can just through-bolt the bracket like on page 6. If you have a tube frame and use the rivet nuts, torque is 75 lb/ft, if through-bolted and using nuts and washers, the torque is 85 lb/ft. I agree with Rene, this is not the place for trying to use a larger self tapper. I would print out a copy of the instructions and take them to the dealer, demanding they fix BOTH brackets correctly. I recommend you go through the whole set-up that the dealer did, because they probably made more installation mistakes and don't have the hitch adjusted properly either.

Nomadb1 did a very good write up on the Reese Dual cam and contributed it to the library.

http://www.rvforum.net/joomla/index.php?option=com_content&view=article&id=517:reese-dual-cam-setup&catid=26&Itemid=132

You may find it very useful.

Kdb, just saw your last post. Thank you. Am I able to still rivet this after they used self tappers. I guess they kept the paper work from me too. I'm never going back there. I'll do the work myself. I'll have to read the tread you linked. Thanks

Rene T

Site Team

I've never seen rivet nuts before but if you can get them locally, I would probably go with them instead of drilling a through hole. You'll need to drill a 11/16" hole for the rivet nuts. I would do it for both holes if they are perfectly centered in the bracket holes or you can just leave the self tapping bolt there. I would check the torque to make sure it's not on the verge of stripping just like the other one did. The gage thickness of the box beam is probably too thin for that size self tapping bolt so it strips out real easy.

I just did a quick search online. The problem you're going to have is finding a supplier of small quantities. Have you tried to contact the dealer and see if he still has them? The so called tech may have just thrown them in his tool box.

http://www.jhpfasteners.com/blind-rivet-large-flange-smooth-body-p-3836-l-en.html

I just did a quick search online. The problem you're going to have is finding a supplier of small quantities. Have you tried to contact the dealer and see if he still has them? The so called tech may have just thrown them in his tool box.

http://www.jhpfasteners.com/blind-rivet-large-flange-smooth-body-p-3836-l-en.html

They are not structural, the bracket loops over the top of the frame and that is where the stress is centered. The bolt in question only locates the bracket when there is no tension on the bars. Once tension is on that bolt could be removed and you would no way be able to move that bracket. I have basically the same setup from Reese and I do not have that bolt, just a locating bolt from the other side, again, not structural.

Rickf1985 said:They are not structural, the bracket loops over the top of the frame and that is where the stress is centered. The bolt in question only locates the bracket when there is no tension on the bars. Once tension is on that bolt could be removed and you would no way be able to move that bracket. I have basically the same setup from Reese and I do not have that bolt, just a locating bolt from the other side, again, not structural.

I'm not sure I'm following you in regards to the bracket. Mine is bolted to the underside of the frame not the top. It looks to me that if I take both screws out the bracket would fall off

Rene T

Site Team

Camben said:Does anyone have experience using rivet nuts??

I've never seen them but it looks pretty simple. Drill the appropriate size hole, drive the nut in the hole till the flange is flush. Insert the bolt and just start tightening. The wall of the nut on the backside collapses and your done.