I semi retired my F250 7.3 diesel last fall, and replaced it with an F150 Super Crew with the 3.5 EB engine.

My TT is only 24' and weighs in about 1880 KG's, so when pulling it with the F250 I just hooked it up straight to the hitch and never bothered with a load balancing hitch.

Now I'm planning to pull the TT down to the coast thru the mountains, and thought that for this lighter truck I'd get a load balancing hitch. I picked up the Reese Pro Series 1200lb round bar weight distribution hitch. I opted for the heavier 1200lb unit because eventually I'll probably want to pull a bigger trailer than the 24' unit I have now.

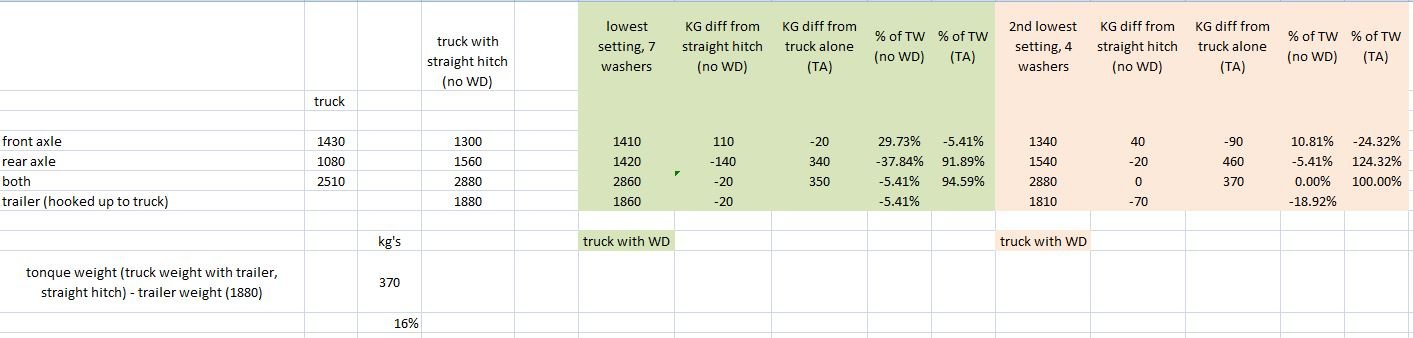

Following instructions and a couple of youtube videos, I've got it set up to what I think is pretty close. I weighed the truck and trailer with the trailer hooked up to a straight hitch on a commercial scale, and got the following:

Front truck axle - 1300 Kg's

Rear truck axle - 1560 kg's

Truck weight - 2880 kg's

trailer axles - 1880 kg's

I set up the Reese hitch to that my front ground to fender well measurement stayed the same, and the rear fender well measurement was within an inch of unloaded measurements. With the trailer level and the ball assembly at it's lowest point the ball on the truck was still over 2" higher than the top of the coupler (instructions said should be within 1"), even with all of the spacer washers used to tilt the ball back, but that's what I had to work with so I hooked the chains up on the 2nd last link and got the correct (according to instructions) measurements on the wheel well to ground differences. I then took it to the scale and got these readings:

Front truck axle - 1410 Kg's

Rear truck axle - 1420 kg's

Truck weight - 2860 kg's

trailer axles - 1860 kg's

It feels ok on the highway, but I'm concerned about the angle of the tension bars. The instructions said that with each washer added the end of the bar would drop 1" or so, so I guess it's ok, but they look a little close to the ground to me. The trailer is also just a tad high in the front, but bubble on a level just edging over the line but still mostly in the middle of the two marks.

I've attached some photos, since I've never used one of these hitches before I want to make sure I have it hooked up correctly and optimally. Any feedback is greatly appreciated.

thanks in advance..

My TT is only 24' and weighs in about 1880 KG's, so when pulling it with the F250 I just hooked it up straight to the hitch and never bothered with a load balancing hitch.

Now I'm planning to pull the TT down to the coast thru the mountains, and thought that for this lighter truck I'd get a load balancing hitch. I picked up the Reese Pro Series 1200lb round bar weight distribution hitch. I opted for the heavier 1200lb unit because eventually I'll probably want to pull a bigger trailer than the 24' unit I have now.

Following instructions and a couple of youtube videos, I've got it set up to what I think is pretty close. I weighed the truck and trailer with the trailer hooked up to a straight hitch on a commercial scale, and got the following:

Front truck axle - 1300 Kg's

Rear truck axle - 1560 kg's

Truck weight - 2880 kg's

trailer axles - 1880 kg's

I set up the Reese hitch to that my front ground to fender well measurement stayed the same, and the rear fender well measurement was within an inch of unloaded measurements. With the trailer level and the ball assembly at it's lowest point the ball on the truck was still over 2" higher than the top of the coupler (instructions said should be within 1"), even with all of the spacer washers used to tilt the ball back, but that's what I had to work with so I hooked the chains up on the 2nd last link and got the correct (according to instructions) measurements on the wheel well to ground differences. I then took it to the scale and got these readings:

Front truck axle - 1410 Kg's

Rear truck axle - 1420 kg's

Truck weight - 2860 kg's

trailer axles - 1860 kg's

It feels ok on the highway, but I'm concerned about the angle of the tension bars. The instructions said that with each washer added the end of the bar would drop 1" or so, so I guess it's ok, but they look a little close to the ground to me. The trailer is also just a tad high in the front, but bubble on a level just edging over the line but still mostly in the middle of the two marks.

I've attached some photos, since I've never used one of these hitches before I want to make sure I have it hooked up correctly and optimally. Any feedback is greatly appreciated.

thanks in advance..