Hi.......... I have a 2003 Komfort 25 travel trailer with a small slide...... This winter the lino on the floor cracked badly. I am going to replace it with vinyl planks. The floor has always squeaked badly when walking on it. I wanted to see if i could do anything with this while the vinyl is removed. I cant see any screws or staples that hold the floor to the frame. Going from underneath would be a huge job as the bottom is enclosed. Anybody have any ideas ? Thanks very much.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Squeaky trailer floor

- Thread starter Bullyus

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

stripit

Well-known member

Years ago I had a 24 ft Prowler with a squeeky floor. We also had a covering under the bottom. It felt and sounded like the plywood floor was making noise as it was laid across the metal cross beams. I cut a section under the area of the noise in the bottom covering. I cut it 3 sides ( big enough so I could sit and have my shoulders up inside while sitting on the ground) with the uncut portion facing forward so when I put the "flap" back in place the wind when driving forward would not catch and peel the flap back open. I used 1X2 wood as a surround to screw the flap back up when done. From under the trailer I had my wife stand inside to walk on the floor to make the squeek. Then drilled and screwed screws through the cross beam into the plywood. Whole job took about 1/2 hour, pretty easy once you get under and see.

Rene T

Site Team

I would use a stud locater then get some self tapping screws with big heads and screw the subfloor down to the cross members. Use a ton of screws

One word: Squeak Enders. You'd still have to access the subfloor area.Hi.......... I have a 2003 Komfort 25 travel trailer with a small slide...... This winter the lino on the floor cracked badly. I am going to replace it with vinyl planks. The floor has always squeaked badly when walking on it. I wanted to see if i could do anything with this while the vinyl is removed. I cant see any screws or staples that hold the floor to the frame. Going from underneath would be a huge job as the bottom is enclosed. Anybody have any ideas ? Thanks very much.

Rene T

Site Team

I don’t believe they would if they use a stud finder and do everything from the top hopefully.One word: Squeak Enders. You'd still have to access the subfloor area.

Just make sure the stud finder will pick up metal studs.

Kirk

Well-known member

This is a new one on me so I looked up Squeak Enders on Amazon. I'm wondering which of those products did you use?One word: Squeak Enders.

We used them on floors with wooden joists ( those with the L bracket, you’d have to match the type to whatever supports the decking.This is a new one on me so I looked up Squeak Enders on Amazon. I'm wondering which of those products did you use?

Thanks for your reply..... Im trying to find something that will work without cutting up the underside. May have to do this in the end if nothing else works. The problem is the sqeak is the whole kitchen floor. Thanks for your input.Years ago I had a 24 ft Prowler with a squeeky floor. We also had a covering under the bottom. It felt and sounded like the plywood floor was making noise as it was laid across the metal cross beams. I cut a section under the area of the noise in the bottom covering. I cut it 3 sides ( big enough so I could sit and have my shoulders up inside while sitting on the ground) with the uncut portion facing forward so when I put the "flap" back in place the wind when driving forward would not catch and peel the flap back open. I used 1X2 wood as a surround to screw the flap back up when done. From under the trailer I had my wife stand inside to walk on the floor to make the squeek. Then drilled and screwed screws through the cross beam into the plywood. Whole job took about 1/2 hour, pretty easy once you get under and see.

Rene T

Site Team

If you should decide to use screws and you’re concerned about the heads sticking up, just use a fostner bit and counterbore a hole about 1/8” deep for the head to sit flush. Then you could always, if needed, fill the hole with some type of floor leveler

Last edited:

Rene T

Site Team

If you should decide to use screws and you’re concerned about the heads sticking up above the floor, Just counterbore a hole with a Forster bit the same thickness as the screw head. Then you could fill the hole with some type of floor leveler

I think its a wierd floor with some type of insulation squished between chipboard. Dont think there are any wood braces below . somehow attached to metal frame . Possibly just around the out side. Im going to remove the lino next week and see what it looks like. Thanks for your input. HemiIf you should decide to use screws and you’re concerned about the heads sticking up, just use a fostner bit and counterbore a hole about 1/8” deep for the head to sit flush. Then you could always, if needed, fill the hole with some type of floor leveler

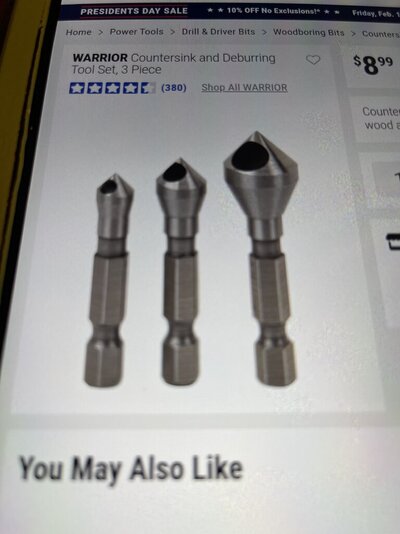

Forstner bits are for drilling holes where a regular drill bit is impractical, a bugle head screw will countersink itself or a countersinking bit which ordinarily can be bought in a set of three different sizes. Meantime if you can locate metal joists just be aware self tapping screws are notoriously bad about spinning out or not holding well. I'd drill a pilot hole then use a course thread metal screw.

Ok... Will do ..Thanks for your help. HemiForstner bits are for drilling holes where a regular drill bit is impractical, a bugle head screw will countersink itself or a countersinking bit which ordinarily can be bought in a set of three different sizes. Meantime if you can locate metal joists just be aware self tapping screws are notoriously bad about spinning out or not holding well. I'd drill a pilot hole then use a course thread metal screw.

Rene T

Site Team

Using a Forster bit will give you a nice flat hole. Using a self sheet metal self tapping screw will have a farely large head and a lot of surface area under the head. You would end up with much more surface area with these screws than you would with your suggested bugle screw.Forstner bits are for drilling holes where a regular drill bit is impractical, a bugle head screw will countersink itself or a countersinking bit which ordinarily can be bought in a set of three different sizes. Meantime if you can locate metal joists just be aware self tapping screws are notoriously bad about spinning out or not holding well. I'd drill a pilot hole then use a course thread metal screw.

For one, It’s forstner and two, bugle head screws are specifically designed to countersink themselves in wood. More surface area is irrelevant. Chasing a pilot hole with a countersink bit would be the ordinary method.Using a Forster bit will give you a nice flat hole. Using a self sheet metal self tapping screw will have a farely large head and a lot of surface area under the head. You would end up with much more surface area with these screws than you would with your suggested bugle screw.

Attachments

Thanks for the reply............. HemiUsing a Forster bit will give you a nice flat hole. Using a self sheet metal self tapping screw will have a farely large head and a lot of surface area under the head. You would end up with much more surface area with these screws than you would with your suggested bugle screw.