larryr

Well-known member

- Joined

- Jun 20, 2016

- Posts

- 70

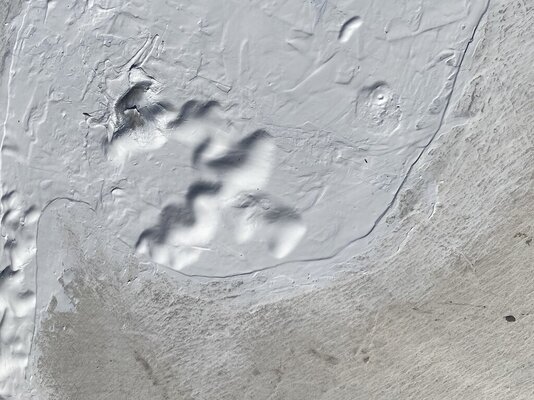

Had a leak coming from the wiring of an old RD9900 sat dish base. Decided to remove the base. Cut back loose sealant, membrane seemed tightly laid down. Prepped with lacquer thinner the day before resealing, an alcohol wipe a few minutes before applying dicor self leveling lap sealant. Ran out of sealant with a bit left to do, went up this morning and found bubbling up. I thought it was sealant, not the membrane and (idiot that I am) popped the bubble, found the membrane has lifted. I'm at a loss and need to find a solution. Pics attached from start to this morning. All of the problem areas are in the footprint of the old dish base and space between dish and vent cover.

Any help in figuring out what the cause is, and what solutions might be available short of re-roofing as the rest appears to be recent and good (don't know the history). TIA, Larry

Any help in figuring out what the cause is, and what solutions might be available short of re-roofing as the rest appears to be recent and good (don't know the history). TIA, Larry