well, it may not be the pump..... now that I have access to the wiring for the pump, I got out my test light and tested, and found no power at the pump connection.

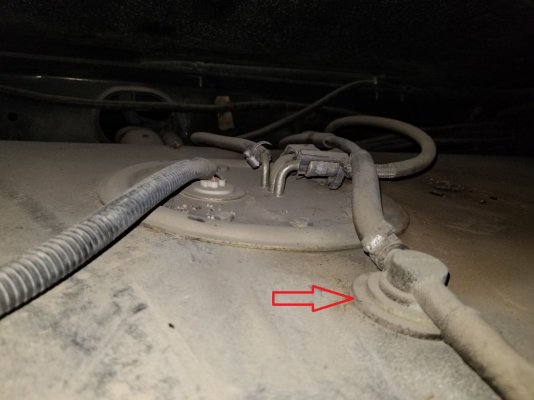

also, it looks like this is NOT the original fuel pump, as the pump itself (with sending unit) is a FOUR wire, which has been spliced into the 3 wire chassis loom. The instructions in the new fuel pump discuss this.

So, back to the drawing board, and troubleshooting. Noticed that the relay, when I pull and replace the fuse (with key on) , closes (clicks) and then 1 second later, clicks again. (it opens) clipped the test light on the connector to the inertia switch, and operated the ignition switch. (OFF to ON, but not cranking) Sure enough, when the ignition is turned on, the circuit is hot for about 1 second, then turns off. ON to STARTING got the same result, test light on for about 1 second, then off.

I swapped out the relay for a known good one, same thing. So, got the wifey off the couch and had her operate the ignition, while I got back and listened for the pump to run, which it did not. (at least I couldn't hear it, or feel anything with my hand on top of it.

I'm stumped. could there be a latching circuit that holds the relay "on"?? (don't see how it could, as the relay socket only uses 4 of the 5 spades of the relay) If the pump is not running, does the relay open on purpose? Heck, I'm not opposed to running a hot (fused) wire back there to run the pump, but there must be a reason for having the relay.

Doesn't the pump have a pressure switch built into it? Or is there perhaps a seperate pressure switch somewhere in the system? (don't see any reference to it in the Service Manual)

I hate to put the new pump in if it is not needed. Guess I'll go back out and cut the wiring to the pump and check continuity thru the motor, to see if it's open. If it IS open, I'll go ahead and replace pump.

as always, I appreciate any suggestions or insight from the "collective mind" of this website, there sure are some sharp individuals here who are generous with their knowledge, and I'm thankful for that!

Cheers! (I'll need more than a cold one tonight if I can't figure this out!)