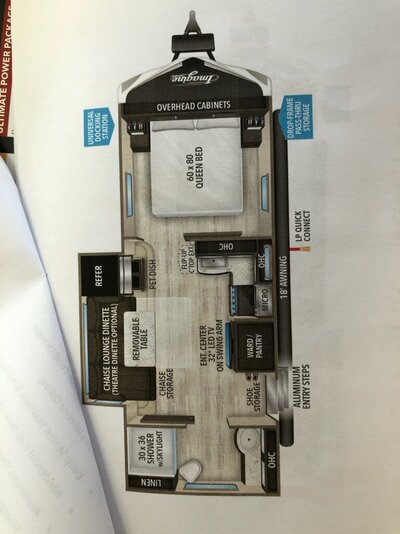

@solarman ok so I could use the current battery lines that run to the hitch mount lead acid battery via a route under the passthrough. Bring them up inside to the battery bank to supply 12v DC to the distro panel? Would I need to increase the guage?

for the few feet diference you make I would suggest you keep them the same.

Then any input if I want the 12/2000 or 12/3000 inverter charger?

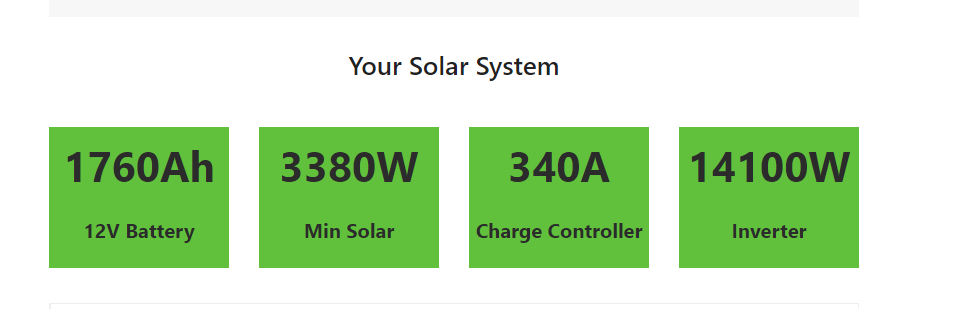

only you know what size inverter will be required, have you summed all your loads and produced a figure ? take some time and add up all the concurrent loads, I have a spreadsheet posted in another thread.. try it, it will help. my only consideration here is if you intend to use a 3000 watt unit with 12 Volts.. that's some 250 Amps peak and it's not a good solution in my opinion.. you wil need to use 4/0 cables and professionally crimped lugs. ( marine or golf cart shops can make these for you )

Battery bank of 300 aH seem sufficient if I have a gen set to back up my solar panels?

the issue here is see is the BMS, be very careful in your choice of battery as a number of "cheaper" batteries ony have a 100 Amp BMS. I would suggest you only draw 50% of the batteries BMS capacity.. over stressing a BMS can lead to premature failure. this is another reason i promote higher voltages. - less current and smaller conductors..

600 vs 800 w of panels? I'm having no luck finding an easy source for residential panels here in MD.

pity you are not closer, I could supply you with panels, sadly the shipping cost to you is unrealistic.

due to the larger size, these have to be shipped freight.

Are there any big advantages to running panels in series or parallel? Ditto on the batteries? (I realize I would have to have 200 aH or 400 aH to run in parallel)

series will allow smaller conductors and higher PV voltages, generally more efficient vs cable and MPPT losses however, shading will destroy output very quickly. parallel is preferred for maximum yield and is what I would recommend for general use in an RV. unless you live in the dessert or an open space..!

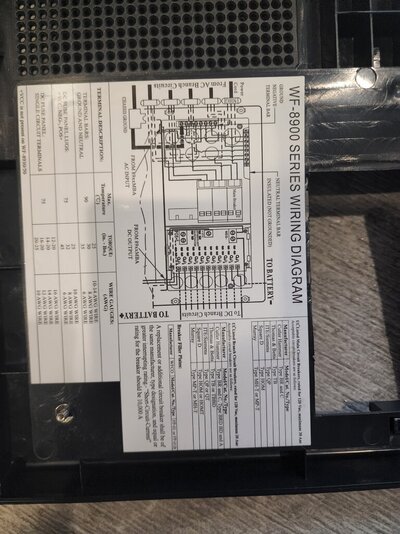

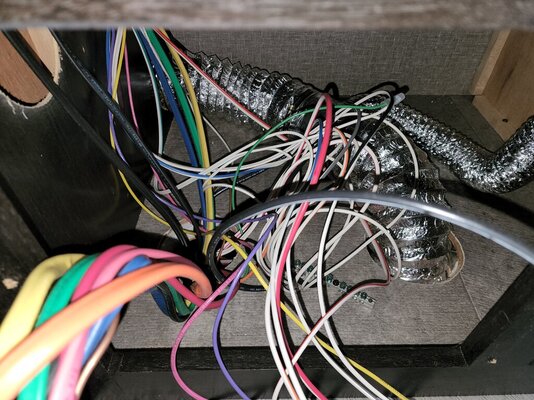

How would I determine cable diameter to get AC power to the panel? I think I can fish it though the same conduit/fenestration as the battery to panel cables?

you will have two cable runs, one from your shore input to the Victron unit and one pair back to the load center. the victron has an auto transfer switch. you would use 10 AWG. ( assuming a 30 Amp system )

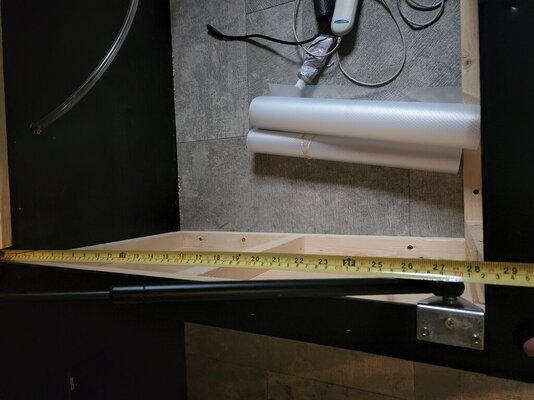

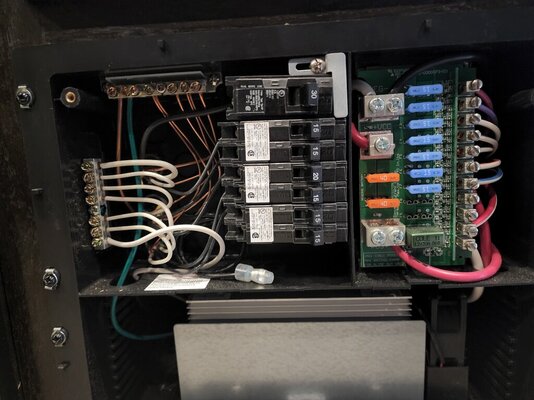

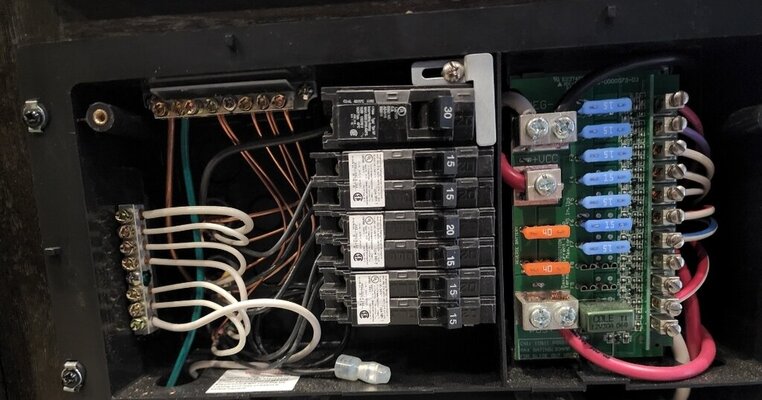

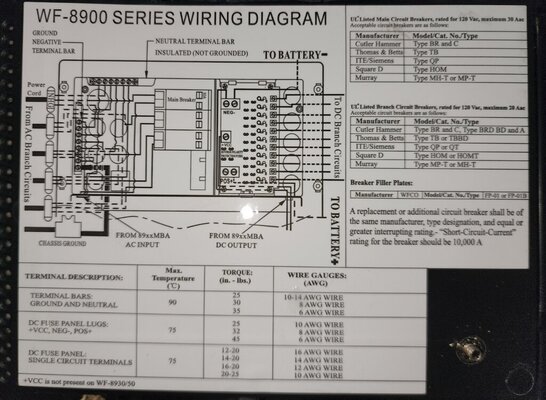

I see the panel has guage ratings on it but if I'm running cable from the inverter that now located further from the panel it'll have to be larger guage? Or I believe there was a discussion of running multiple cables instead of replacing them outright?

View attachment 157494View attachment 157495View attachment 157496

I see no harm leaving the charger in place, it will not fully charge a lithium anyway, the victron unit will provide charging as necessary.