I am hooking up the breaker panel and need some guidance. The panel is being fed by 10/3 SO cable. My question is can I or how do I connect the fine stranded wire to the breaker and neutral / ground bars? It's a small panel so not much room.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY build

- Thread starter Acman44

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Gary RV_Wizard

Site Team

Hard to guess without firsthand knowledge of the panel you are using (a photo would help). Most are designed with solid wires in mind, so stranded can be frustrating. Are the connection terminals a screw type that you wrap around, or a slot that you insert the wire into? Most load centers use the slot type. If slot, is there a small flat plate that clamps down on the wire, or just the screw point in direct contact with the wire? The better panels will have the plate and those hold stranded wire adequately. Direct screw contact makes a poor connection on stranded wire. You might even want to add a wire ferrule to contain the strands.

Rene T

Site Team

Or could you solder the ends?Hard to guess without firsthand knowledge of the panel you are using (a photo would help). Most are designed with solid wires in mind, so stranded can be frustrating. Are the connection terminals a screw type that you wrap around, or a slot that you insert the wire into? Most load centers use the slot type. If slot, is there a small flat plate that clamps down on the wire, or just the screw point in direct contact with the wire? The better panels will have the plate and those hold stranded wire adequately. Direct screw contact makes a poor connection on stranded wire. You might even want to add a wire ferrule to contain the strands.

Lou Schneider

Site Team

- Joined

- Mar 14, 2005

- Posts

- 13,249

The main issue is keeping all of the strands under the screw as you tighten it down. Cut the insulation off of the wire on the long side so you can grab the end of the wire with a pair of pliers and keep tension on it as you tighten the screw. Then clip off the excess if it poses a hazard being left in place.

Mark_K5LXP

Well-known member

Gary RV_Wizard

Site Team

I think soldering works if properly done, but apparently amateurs don't often get it right. Thus the advice to avoid it. I've used solder on the ends of small stranded wires (successfully, I think), but 10 ga or larger would be a challenge for me. I attempted it on some 6 ga and failed miserably.

Mark_K5LXP

Well-known member

I may be all wet but I'm pretty sure tinning isn't kosher per NEC, as solder can cold flow under the pressure of a set screw and loosen over time.

Mark B.

Albuquerque, NM

Mark B.

Albuquerque, NM

CharlesinGA

Well-known member

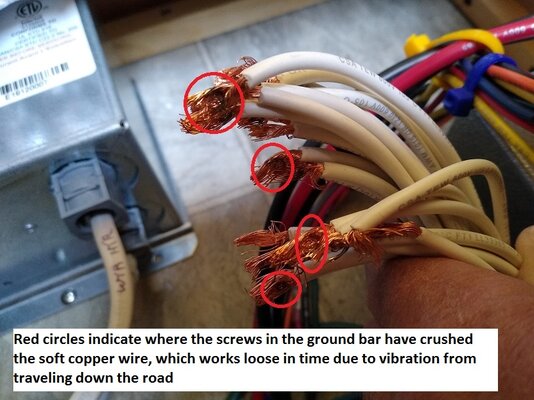

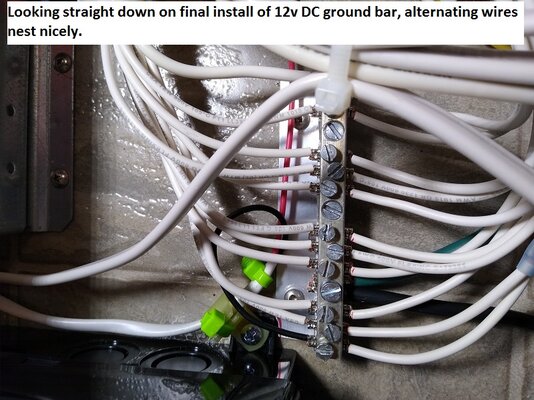

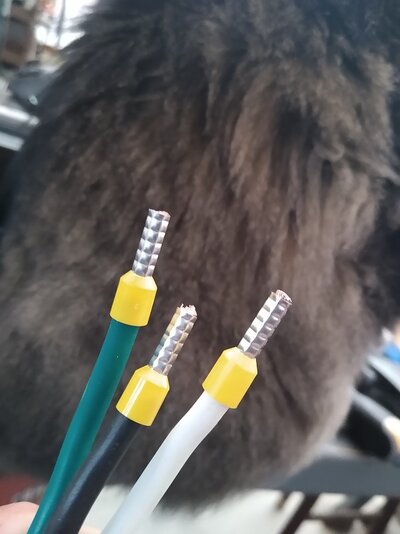

Ferrules, either with collars or not, are in my opinion the best way to go. I installed a Progressive Industries TT30R end on my old 25ft shore cord to make an extension, and I used ferrules. Crimpers are fairly inexpensive, I bought both square and hexagon crimpers and ended up using ferrules without collars for much of my work. Pics attached are using ferrules inside that female cord end, and also when I did the 12v DC ground bar and wires with ferrules.

Charles

Ferrule Documents

Ferrules Direct

https://www.amazon.com/gp/product/B07MZWZYMJ/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8

Charles

Ferrule Documents

Ferrules Direct

https://www.amazon.com/gp/product/B07MZWZYMJ/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=UTF8

Attachments

-

Ferrule inst ground wires with strands flayed out.jpg330.4 KB · Views: 6

Ferrule inst ground wires with strands flayed out.jpg330.4 KB · Views: 6 -

Ferrule inst ground wires all done hex crimps.jpg297.8 KB · Views: 6

Ferrule inst ground wires all done hex crimps.jpg297.8 KB · Views: 6 -

Ferrule inst ground bar inst completed.jpg355 KB · Views: 6

Ferrule inst ground bar inst completed.jpg355 KB · Views: 6 -

Ferrule inst hex crimping tool.jpg350.7 KB · Views: 6

Ferrule inst hex crimping tool.jpg350.7 KB · Views: 6 -

Shore Cord Extension 4 ends cut and ferrules installed.jpg249.8 KB · Views: 3

Shore Cord Extension 4 ends cut and ferrules installed.jpg249.8 KB · Views: 3 -

Shore Cord Extension 8 ready to install back cover.jpg254.2 KB · Views: 4

Shore Cord Extension 8 ready to install back cover.jpg254.2 KB · Views: 4

Last edited:

CharlesinGA

Well-known member

The question is where is this 10/3 SO cord coming from? I've seen shore cords hardwired into breaker panels, mine was, and its not a pretty picture to put that fine stranded wire into a breaker under a set screw.

If you are simply coming from an outside turnlock power inlet, to the breaker panel, you would be better off to use individual THHN 10AWG wires and run them in a flex conduit. SO, by code, is not allowed to be used for point to point permanent wiring (nor is any cord) That is the purpose of either cables (ie Romex®) or individual wires such as THHN. Here is a pic or two of how I did this when I eliminated my hardwired shore cord and plug in for the onboard generator and installed a turn lock outside and a auto transfer switch to connect the generator.

The 10 AWG THHN is stranded but it is a coarse strand that is designed to be used under set screws and the like. THHN is what is commonly used to pull thru conduits. The blue conduit is what is commonly called "Smurf tubing" and is found in Home Depot. It is a rated Electrical Nonmetallic Tubing. Carlon only makes straight ends for it however, no elbows or other fittings. They have 25ft rolls, rather inexpensive. This is frequently used to route wiring thru walls with metal studs.

Charles

If you are simply coming from an outside turnlock power inlet, to the breaker panel, you would be better off to use individual THHN 10AWG wires and run them in a flex conduit. SO, by code, is not allowed to be used for point to point permanent wiring (nor is any cord) That is the purpose of either cables (ie Romex®) or individual wires such as THHN. Here is a pic or two of how I did this when I eliminated my hardwired shore cord and plug in for the onboard generator and installed a turn lock outside and a auto transfer switch to connect the generator.

The 10 AWG THHN is stranded but it is a coarse strand that is designed to be used under set screws and the like. THHN is what is commonly used to pull thru conduits. The blue conduit is what is commonly called "Smurf tubing" and is found in Home Depot. It is a rated Electrical Nonmetallic Tubing. Carlon only makes straight ends for it however, no elbows or other fittings. They have 25ft rolls, rather inexpensive. This is frequently used to route wiring thru walls with metal studs.

Charles

Attachments

Last edited:

SeilerBird

Well-known member

Well done Charles. I don't believe in using solder on any vehicle since vibration can destroy a solder joint.