X-Roughneck Strike 3

Well-known member

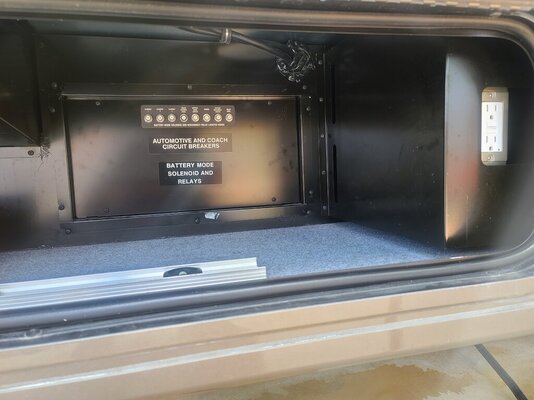

Hello board. I am looking for Online documentation that shows the Factory Length of battery cables that connect at the House Batteries. Is there WGO documentation out there that show this?

I have ordered some parts from WGO parts online for the House Battery Hold down bracket. Trying to go back Fresh when the parts arrive as I am replacing the two House batteries painting the tray etc. Freshening things up before battery acid does any real damage.

I am avoiding pulling the batts and taking this off until I have parts in hand. I am wanting to order new cables with better pressed on ends / connectors at the battery if I can find exact lengths using online documentation.

I emailed WGO customer support and asked.

JD

I have ordered some parts from WGO parts online for the House Battery Hold down bracket. Trying to go back Fresh when the parts arrive as I am replacing the two House batteries painting the tray etc. Freshening things up before battery acid does any real damage.

I am avoiding pulling the batts and taking this off until I have parts in hand. I am wanting to order new cables with better pressed on ends / connectors at the battery if I can find exact lengths using online documentation.

I emailed WGO customer support and asked.

JD

Last edited: