Update.....

So it turns out both the circuit board and the regulator were faulty.

After much probing / testing with the old Fluke I was pointing the problem more toward the circuit board than the regulator.

I purchased both, installed the new board with the old regulator and it fired right up and continued to run, (first victory)..but...the a.c. output voltage was 164v, so...plugged in the new regulator and now it's a rock solid 120v +- 0.4v

Next step is to verify hz with and without load per service manual and make adjustments if needed.

I scored the circuit board on Amazon listed as a like new, no box sale for $59.00 Prime + tax

All their other listings were @$146

The regulator came from getrvparts.com for $237 versus the going rate of $295 elsewhere.

So all in I'm at $329 for both..call it a win I guess.

Next is to do some insulation and possibly some exhaust mods.

Oh, and buy a Slick Stick.

Thanks again for the pointers fellas !

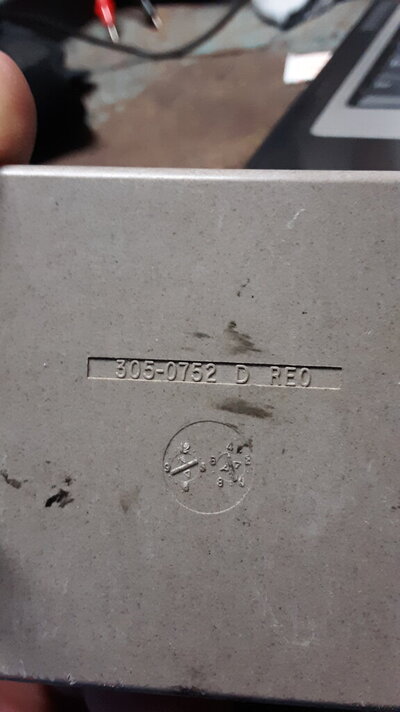

Old junk