JerArdra

Well-known member

- Joined

- Mar 3, 2005

- Posts

- 1,814

7/7/05

All,

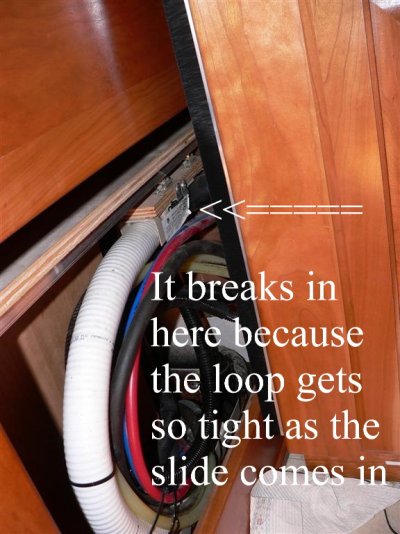

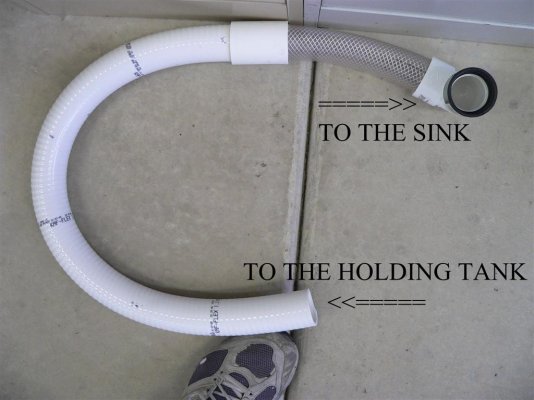

This involves the kitchen sink drain pipe on a kitchen slide out MH. Mine broke! The attached photo shows the looped 1-1/2 inch flexible drain line when the slide is extended. The problem is that when the slide is retracted (closed) the area where the arrow is would move toward you as you are looking at this photo (this is toward the center of the coach). During that movement the the loop at the top gets shorter and there is a tremendous pressure pulling down on the flexible pipe where I marked with the arrow. Over time this results in tearing the flexible pipe and thus a leaking drain line.

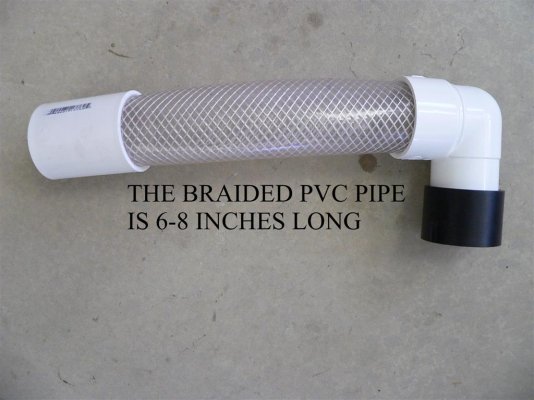

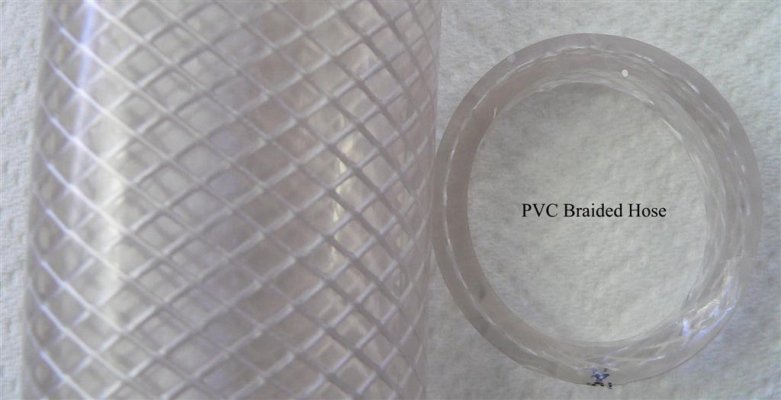

One solution is a more flexible 1-1/2 hose but you do need some rigidity so the loop moves smoothly as the slide moves both in and out.

Another solution would be a flexible joint that would interconnect the flexible pipe to the hard ABS plastic sink drain line in the area whee I have the arrow on the photo.

I have two questions (this is a drain line so there is NO pressure)...

1. Does any one know of the 1-1/2 inch flexible pipe joint. What I picture is a connector that would interconnect where the flexible pipe joins the hard plastic ABS sink drain pipe and that also has a ball joint in the middle so it can flex downward 20-30 degrees when the slide is retracted in. For example, if you were holding your hand palm down and the bent you index finger down it would flex at the first joint. All you need is about a 20 degree downward flex so as the loop gets shorted and begins to pull downward on the flexible hose there is less downward pressure on the flexible hose. Also when you again extend the slide the flexible joint would go straight for draining.

2. Any other ideas?

Thanks to all,

JerryF

All,

This involves the kitchen sink drain pipe on a kitchen slide out MH. Mine broke! The attached photo shows the looped 1-1/2 inch flexible drain line when the slide is extended. The problem is that when the slide is retracted (closed) the area where the arrow is would move toward you as you are looking at this photo (this is toward the center of the coach). During that movement the the loop at the top gets shorter and there is a tremendous pressure pulling down on the flexible pipe where I marked with the arrow. Over time this results in tearing the flexible pipe and thus a leaking drain line.

One solution is a more flexible 1-1/2 hose but you do need some rigidity so the loop moves smoothly as the slide moves both in and out.

Another solution would be a flexible joint that would interconnect the flexible pipe to the hard ABS plastic sink drain line in the area whee I have the arrow on the photo.

I have two questions (this is a drain line so there is NO pressure)...

1. Does any one know of the 1-1/2 inch flexible pipe joint. What I picture is a connector that would interconnect where the flexible pipe joins the hard plastic ABS sink drain pipe and that also has a ball joint in the middle so it can flex downward 20-30 degrees when the slide is retracted in. For example, if you were holding your hand palm down and the bent you index finger down it would flex at the first joint. All you need is about a 20 degree downward flex so as the loop gets shorted and begins to pull downward on the flexible hose there is less downward pressure on the flexible hose. Also when you again extend the slide the flexible joint would go straight for draining.

2. Any other ideas?

Thanks to all,

JerryF