CharlesinGA

Well-known member

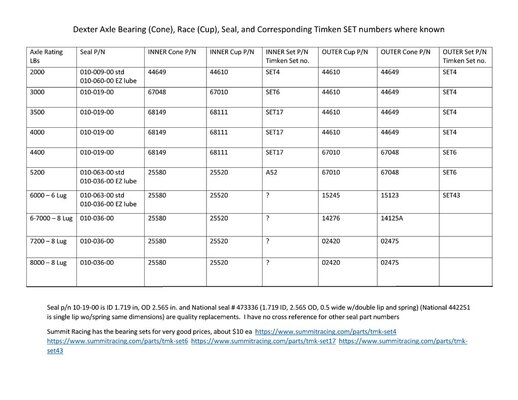

I'm sure that in a week or so, someone will ask the question, but for now, I'm going to post this chart I made of bearing, race and seal part numbers for Dexter axles. Now many people have Lippert axles and my one experience is with a Lippert 3500 lb axle and it uses the same bearings, brakes, hubs, etc as the Dexter, so take that for what its worth.

For Dexter there are two references, one is the 600-8K lb Complete Service Manual and the other is the 600-8K lb Parts Catalog. So if you feel the need to verify any of the bearing numbers in my chart, here's where I got them from. Normally bearings (cones) and races (cups) are packaged and sold separately (unless they are the cheap auto parts bearings). If you go to an industrial supplier, they will have or have to order all the components individually. Timken does package the same bearings and races in sets. They are assigned set numbers and that is the reason for the two columns with set numbers in them (notice no space between the word SET and the number, ie SET6). Also read my note at the bottom about one source I have found for the sets. If you buy enough for two axles, and throw a tube of grease in the order you will push it just over $100 and get the free shipping.

Here is the Lippert Axle Manual. For whatever reason, the Lippert site will not allow me to access any of the manual, I keep getting errors, so I give you this link instead. Possibly the web site is partially down IDK, I'll keep trying.

There is a lot to replacing bearings and races. Here is a suggestion of what you will need once you get the hubs removed. You need to have decent mechanical aptitude and if you don't please find someone who does to work with you on how to do this.

For Dexter there are two references, one is the 600-8K lb Complete Service Manual and the other is the 600-8K lb Parts Catalog. So if you feel the need to verify any of the bearing numbers in my chart, here's where I got them from. Normally bearings (cones) and races (cups) are packaged and sold separately (unless they are the cheap auto parts bearings). If you go to an industrial supplier, they will have or have to order all the components individually. Timken does package the same bearings and races in sets. They are assigned set numbers and that is the reason for the two columns with set numbers in them (notice no space between the word SET and the number, ie SET6). Also read my note at the bottom about one source I have found for the sets. If you buy enough for two axles, and throw a tube of grease in the order you will push it just over $100 and get the free shipping.

Here is the Lippert Axle Manual. For whatever reason, the Lippert site will not allow me to access any of the manual, I keep getting errors, so I give you this link instead. Possibly the web site is partially down IDK, I'll keep trying.

There is a lot to replacing bearings and races. Here is a suggestion of what you will need once you get the hubs removed. You need to have decent mechanical aptitude and if you don't please find someone who does to work with you on how to do this.

| For anyone replacing the bearings and races you need a few tools. First is a 2 lb or so Ball Pein hammer One point five (thats half way between first and second) a seal puller is helpful but certainly not necessary, I've struggled for years without and someday soon I may break down and buy one.

Second is a long, easy to grasp tapered steel drift to drive out the races. Needs to be about 8 to 12 inches long and have a 1/4 inch or so tip. Wear safety glasses as steel chips can fly when hammering steel on steel on steel. I miss the old hubs like cars used that had notches cast into the hub to give you full purchase on the back side of the race/cup to drive it out. Third is a good solid wood block to place the hub on, on the floor to hammer on. You also need a couple of more wooden blocks to place under the edges of the drum when driving out the outer race. Fourth is a bearing race driver set, which you can usually borrow from most auto parts stores. Make sure the set has the sizes you need to fit the races. Bearing Race and Seal Driver Set 10 Pc.  Fifth (optional) is a bearing packer. If you are packing 8 bearings it is a chore to do it by hand. This type of bearing packer makes short work of it, but its still a messy proposition. Amazon.com: Lisle 34550 Handy Packer Bearing Packer : Automotive  Here is the chart I promised. Since I cannot upload MSWord files or PDF's this is a JPG image file, which if you click on it, will enlarge and be easily readable. |

| Charles |

Attachments

Last edited: