chaostactics

Well-known member

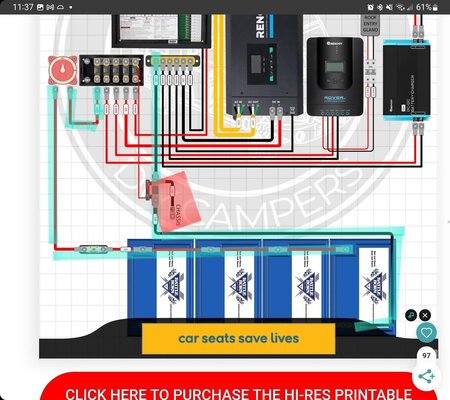

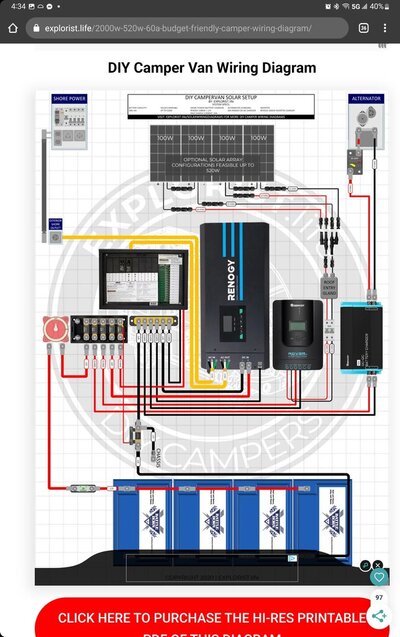

I'm getting ready to mount a solar system. Batteries are going inside immediately on the other side of the bulkhead of my passthrough between my passthrough and my under bed storage.

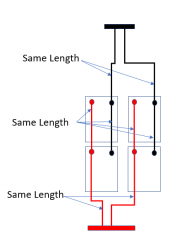

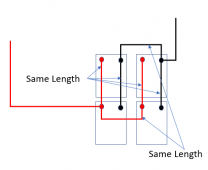

Part of the wiring for this is that I need to pick up chassis ground with a minimal amount of wire run.

What's anyone's best suggestion for tapping safely for a chassis ground?

Part of the wiring for this is that I need to pick up chassis ground with a minimal amount of wire run.

What's anyone's best suggestion for tapping safely for a chassis ground?