John From Detroit

Well-known member

When it comes to broken windshields I do not see how a 3-jack system is any different from a 4-jack where the two front jacks are connected in tandem via a "T" fitting.

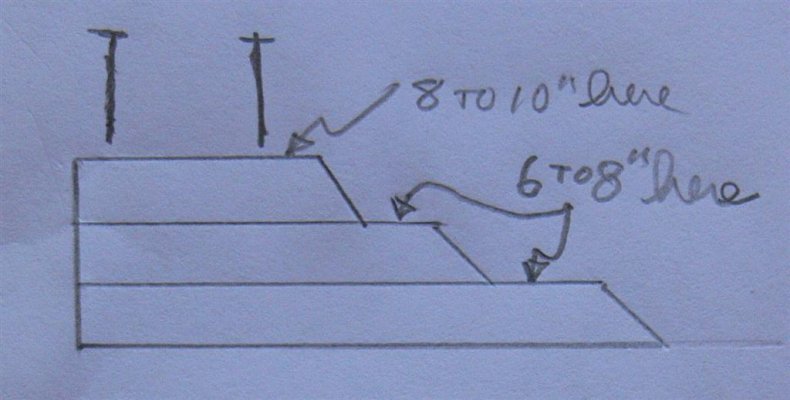

You still put the front jacks down first (this was not properly explained to me by the dealership) and this provides a pivot point as fluid can move jack to jack as you do the side to side leveling using the rear jacks only.

It also splits the load of the front end between the two jacks, putting a lot less stress on things down under

Now: If you want to talk about true 4=jack systems where every jack has it's own valve and their combined actions are computer controlled.

The MTBF for computers is way way lower than the MTBF for a "T" fitting. In fact where as T fittings have but one practical failure mode (Leak) Computers have many and some of them can be a real PITA

You still put the front jacks down first (this was not properly explained to me by the dealership) and this provides a pivot point as fluid can move jack to jack as you do the side to side leveling using the rear jacks only.

It also splits the load of the front end between the two jacks, putting a lot less stress on things down under

Now: If you want to talk about true 4=jack systems where every jack has it's own valve and their combined actions are computer controlled.

The MTBF for computers is way way lower than the MTBF for a "T" fitting. In fact where as T fittings have but one practical failure mode (Leak) Computers have many and some of them can be a real PITA