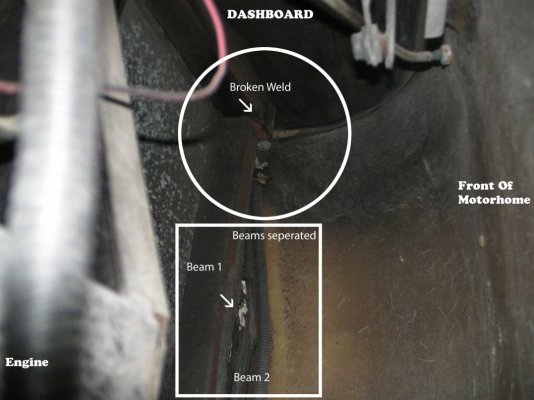

I had a problem with my front window moving while driving and found the reason so I felt it deserved another thread. One of the front support beams snapped at the weld point- and is causing the front to move going down the road and around curves. I assume its also why my window is starting to pop out. The beam that snapped is right under the drivers side dashboard. The weld points are off by over an inch so I assume everything is not square. To reweld is not a big deal because its very easy to get too. My coach does not have leveling jacks so how do I get the steel bars in place (get everything square) to weld them back together?

90 Fleetwood Flair 26'

I attached a picture of the actual problem

90 Fleetwood Flair 26'

I attached a picture of the actual problem