You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Onan generator oil change

- Thread starter Fcranger

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

Not sure about parking at an angle...probably would help, but if this new improved SPEC L plug w/sealing washer stops my leak, I'll likely just leave it in place and use the suction method thereafter. I'm going to use the white liquid PTFE Teflon sealant on the three 360 degree bottom threads, per the Onan engineer's advice (not teflon tape).

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

Just received my new improved drain plug and sealing washer from Onan...they don't fit into the pre-SPEC L oil base that I have (SPEC K). Apparently, with SPEC L, Onan changed the drain plug thread from 1/4"-18 NPT tapered thread to a 3/8" standard (NON-tapered) course thread, in conjunction with adding the plug flange and the sealing washer, but failed to change the oil base part number 102-1444. I was assured that this doesn't happen, and that the new plug and washer would fit into ANY 102-1444 oil base, but not so. The parts person checked the latest parts manual and it still shows the same 102-1444 oil base part number, so they are going to create a new part number for the 3/8" NON-tapered drain plug thread oil base, which has been in use starting with SPEC L (maybe started in 2003?).

Rather than pay over $100 for new 3/8" NON-tapered drain plug thread oil base to go with my new improved oil plug and sealing washer, I'll just take Gary's advice and see what Napa Auto Parts has to offer, and if I can't find anything there, or elsewhere, then I'll just seal the hell out of the old plug to stop my leak, and then use the suction method suggested for my oil changes in the future.

Rather than pay over $100 for new 3/8" NON-tapered drain plug thread oil base to go with my new improved oil plug and sealing washer, I'll just take Gary's advice and see what Napa Auto Parts has to offer, and if I can't find anything there, or elsewhere, then I'll just seal the hell out of the old plug to stop my leak, and then use the suction method suggested for my oil changes in the future.

Rene T

Site Team

soyjer said:Onan changed the drain plug thread from 1/4"-18 NPT tapered thread to a 3/8" standard (NON-tapered) course thread, in conjunction with adding the plug flange and the sealing washer,

That confirms what I said earlier that you wouldn't have a pipe thread on a plug along with a flange for a gasket. They probably changed the style because they were having issues with sealing with a pipe thread and probably excerpting so much pressure that the casing would crack. You should take a good look at yours for a crack. I believe you're going to find that you have female pipe threads in the hole and that the plugs that Gary talked about would probably not work because what I saw, they all had straight thread. Do you have the option of removing the pan, drilling out the pipe threads and taping the hole for a straight thread. Keep in mind that you'll need the face of the hole machined flat to accept the gasket. Also the hole would have to be perpendicular to the machined gasket face. Go to your local auto parts store and see what the largest straight plug would be. You may be able to get away with a 1/2-20" NF thread.

Here is another option: https://www.youtube.com/watch?v=AnP1HQkq70s

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

The plug that Gary linked to was a 1/4"-18NPT tapered plug just like mine, it was just in stainless steel and had a magnet in it. It would work as a direct replacement for my plug, but I'm trying to do better than that, if possible.

I gave up pursuing a replacement NPT plug when Onan told me (wrongly, it turns out) that their new improved plug with sealing washer would fit into ANY 102-1444 oil base. Now that I know that is untrue, I'm back to pursuing a replacement plug. I'd still like to find a 1/4"-18 NPT plug with a flange on it that is long enough that I can "stack" washers/gaskets on it, so that I'd have the "best of both worlds" but, failing that, I'll use whatever sealant necessary to make my old plug seal, even if it has to be permanent.

There may be an air compressor drain plug or something like that out there that is long enough...I'm going to see what Napa has.

As far as re-doing the threads in the hole, fortunately the generator only holds 1.6 qts., and so using the suction method to change the oil is actually going to be easier than having to use a drain plug. I took another look at the drain hole with a magnifying glass yesterday after cleaning it out with alcohol, and it looks absolutely pristine, as does the plug. Doesn't eliminate the possibility of a hairline crack, but probably means that some sort of sealant will be able to permanently seal the leak. Tried to take a pic, but my batteries died. Will try again. I found this picture of the head of the old-style NPT plug (like mine) online:

I gave up pursuing a replacement NPT plug when Onan told me (wrongly, it turns out) that their new improved plug with sealing washer would fit into ANY 102-1444 oil base. Now that I know that is untrue, I'm back to pursuing a replacement plug. I'd still like to find a 1/4"-18 NPT plug with a flange on it that is long enough that I can "stack" washers/gaskets on it, so that I'd have the "best of both worlds" but, failing that, I'll use whatever sealant necessary to make my old plug seal, even if it has to be permanent.

There may be an air compressor drain plug or something like that out there that is long enough...I'm going to see what Napa has.

As far as re-doing the threads in the hole, fortunately the generator only holds 1.6 qts., and so using the suction method to change the oil is actually going to be easier than having to use a drain plug. I took another look at the drain hole with a magnifying glass yesterday after cleaning it out with alcohol, and it looks absolutely pristine, as does the plug. Doesn't eliminate the possibility of a hairline crack, but probably means that some sort of sealant will be able to permanently seal the leak. Tried to take a pic, but my batteries died. Will try again. I found this picture of the head of the old-style NPT plug (like mine) online:

Attachments

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

Was unable to find a 1/4-18 NPT tapered plug with a flange on it...which makes sense...so I just cleaned out the hole and old plug with alcohol, and then used Permatex 80632 Thread Sealant with PTFE on the final three threads of the plug (any above that would end up in the crankcase due to the drain hole "cut-outs"), then torqued the plug to 17 lbs-ft (I'm still leery of the specified 21 lbs-ft, because even 17 lbs-ft seems WAY too high for only having three 360 degree threads present to keep the aluminum oil base from cracking). I'll let the Permatex 80632 Thread Sealant with PTFE cure for at least 72 hours, then add oil and see if it still leaks. The new SPEC L style drain plugs with flange and aluminum sealing washer have M12-1.5 NON-tapered threads and require a matching new style oil base.

Attachments

-

Onan 4KY SPEC K Oil Drain1.JPG16.1 KB · Views: 19

Onan 4KY SPEC K Oil Drain1.JPG16.1 KB · Views: 19 -

Onan 4KY SPEC K Oil Drain2.JPG17.1 KB · Views: 16

Onan 4KY SPEC K Oil Drain2.JPG17.1 KB · Views: 16 -

Onan 4KY SPEC K Oil Drain.JPG117.2 KB · Views: 16

Onan 4KY SPEC K Oil Drain.JPG117.2 KB · Views: 16 -

Onan 4KY SPEC K Oil Drain Plug OLD1.JPG7.9 KB · Views: 19

Onan 4KY SPEC K Oil Drain Plug OLD1.JPG7.9 KB · Views: 19 -

Onan 4KY SPEC K Oil Drain Plug OLD2.JPG5.7 KB · Views: 18

Onan 4KY SPEC K Oil Drain Plug OLD2.JPG5.7 KB · Views: 18 -

Onan 4KY SPEC L Oil Drain Plug NEW.JPG20.1 KB · Views: 20

Onan 4KY SPEC L Oil Drain Plug NEW.JPG20.1 KB · Views: 20

Charlie 5320

Well-known member

If that were mine I'd still get a stainless pipe nipple and screw it in, mark it then take it back out, notch the nipple to match the notches in the pan, then use a thread locker for sealant. Then install a brass ball valve with a stainless plug. That way you won't just have 3 threads to seal it with. That is a poor deal in my opinion, can't believe onan would engineer something like that. Don't see how they could ever keep that from leaking.

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

92GA said:If that were mine I'd still get a stainless pipe nipple and screw it in, mark it then take it back out, notch the nipple to match the notches in the pan, then use a thread locker for sealant. Then install a brass ball valve with a stainless plug. That way you won't just have 3 threads to seal it with. That is a poor deal in my opinion, can't believe onan would engineer something like that. Don't see how they could ever keep that from leaking.

Yeah...I can't think of a scenario where having the drain hole extend below the bottom of the oil pan would be a problem, so I don't know why they would have gone with this "cut-out volcano" design. Your fix would be the way to go if draining out of the drain hole were required, but thankfully this thing only holds 1.6 quarts of oil and so I'll just use a suction device once I get the drain plug to stop leaking.

I was actually hoping to hear from people with experience with aluminum oil pans telling me that the factory specified 21 lbs-ft is just fine, but instead I only heard from people telling me just the opposite, including an Onan engineer with decades of Onan experience, who told me that 21 lbs-ft was too high and that 5-8 lbs-ft sounded about right. The factory specified 21 lbs-ft may, indeed, be just fine, but even 15 lbs-ft was feeling very risky to me as I tightened the plug, and a new oil base is about $150, and so I wanted to be as cautious as possible to avoid cracking or stripping the oil base, if possible. I have no way of knowing how many of these 1/4-18 NPT thread oil bases have been stripped or cracked over the years by oil changers using the factory specified 21 lbs-ft, but Onan DID redesign the oil base hole and plug with SPEC L to an M12-1.5 NON-tapered thread hole and a plug with a flange and sealing washer, and so there MUST have been a REASON for that change being made...such as leaking drain plugs or stripped or cracked oil bases?

Stephen S.

Well-known member

soyjer said:Yeah...I can't think of a scenario where having the drain hole extend below the bottom of the oil pan would be a problem, so I don't know why they would have gone with this "cut-out volcano" design. Your fix would be the way to go if draining out of the drain hole were required, but thankfully this thing only holds 1.6 quarts of oil and so I'll just use a suction device once I get the drain plug to stop leaking.

I was actually hoping to hear from people with experience with aluminum oil pans telling me that the factory specified 21 lbs-ft is just fine, but instead I only heard from people telling me just the opposite, including an Onan engineer with decades of Onan experience, who told me that 21 lbs-ft was too high and that 5-8 lbs-ft sounded about right. The factory specified 21 lbs-ft may, indeed, be just fine, but even 15 lbs-ft was feeling very risky to me as I tightened the plug, and a new oil base is about $150, and so I wanted to be as cautious as possible to avoid cracking or stripping the oil base, if possible. I have no way of knowing how many of these 1/4-18 NPT thread oil bases have been stripped or cracked over the years by oil changers using the factory specified 21 lbs-ft, but Onan DID redesign the oil base hole and plug with SPEC L to an M12-1.5 NON-tapered thread hole and a plug with a flange and sealing washer, and so there MUST have been a REASON for that change being made...such as leaking drain plugs or stripped or cracked oil bases?

From my experience with aluminum motorcycle engines and their oil drain plugs I'd believe 21 inch/lbs before I'd crank a plug to 21 ft/lbs.

Those things go on just a bit past finger tight! Old mechanic taught me to twist it on, then give it a light tug with a wrench, no more.

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

srs713 said:From my experience with aluminum motorcycle engines and their oil drain plugs I'd believe 21 inch/lbs before I'd crank a plug to 21 ft/lbs.

Those things go on just a bit past finger tight! Old mechanic taught me to twist it on, then give it a light tug with a wrench, no more.

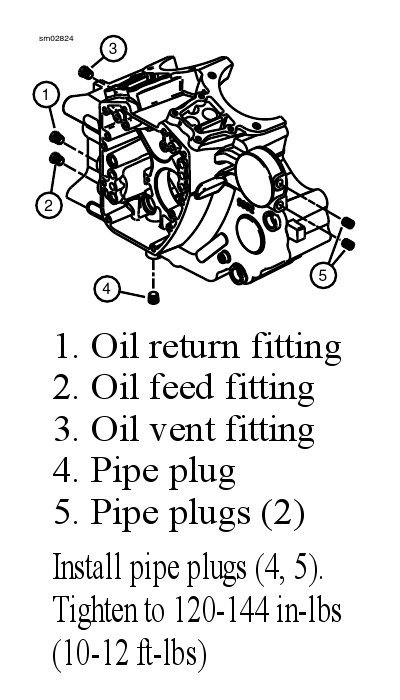

21 ft/lbs does seem high. The only other 1/4" NPT crankcase plug that I could find is the "Dry Sump Plug" used on many Harley-Davidson Softail Models, which is torque spec'd at 10-12 ft-lbs, and is semi-permanently installed at the factory using Loctite 565. Apparently many Harley owners have stripped/cracked their Harley's crankcase by over-tightening these plugs, likely after removing them believing that they are the oil change drain plug, which they are not:

2013 Harley-Davidson Softail Models

Service Manual 99482-13A

Attachments

soyjer

Well-known member

- Joined

- Jul 12, 2014

- Posts

- 51

soyjer said:Regarding my other question about slow oil refilling, I learned today that the problem is that the air above the oil in the oil pan must pass through a tight restriction to reach the valve cover area, and for that reason you must "pump" out the air as you are adding oil in order to be able to quickly refill the oil pan with 1.6 quarts of oil. Fortunately, the breather valve that allows air out of the valve cover area into the atmosphere is a one-way valve, and so you just need to remove the rubber hose from the fitting on the top of the valve cover, then connect a 1/2" I.D. tube connected to a syringe or turkey baster to the fitting on the valve cover, and then pump the syringe or turkey baster to draw air from the oil pan through the "tight restriction" and pass it out the breather valve as you are adding oil to the oil pan. Be careful not to add more than 1.6 quarts, and I'd advise pausing at about 1.3 quarts and maybe turning over the engine before proceeding further, because I'm not sure that the oil pan will hold the full 1.6 quarts without doing so.

I also tried an alternate method of inserting a curved tube into the filler hole until its far end surfaced above the oil level, to see if this "drain" would allow air to escape fast enough to speed up the oil filling process, but it didn't help unless I used a syringe to actively suck air out while filling the oil pan with oil, and that is a lot more trouble and mess than just doing it the above way.

I used Permatex 80632 Thread Sealant with PTFE and 17 ft-lbs torque on the drain plug, and it seems to have solved my oil leak problem...after 96 hours of curing I ran the generator for 2 hours without leaks.

While filling with oil, I noticed that my "suction on vent tube" method of removing air from the crankcase to allow the oil to enter faster wasn't working the way I had previously observed...this time the reed valve wasn't allowing me to just pump the air out...instead I had to remove the hose after each pump stroke or the return stroke would just push the air right back into the crankcase...the reed valve just wasn't allowing the air to exit the engine this time, for some reason. Next time I'll try again to see if I can get the " curved tube" method of venting the crankcase to work, by again running a vinyl hose down the dipstick hole and up into the crankcase air chamber (and then blow any oil out of it) to provide a constant vent for the air to escape while filling with oil. Only reason I can think of that it wouldn't work would be if the air hose diameter wasn't large enough to allow the air to exit fast enough. I thought that I was pouring slowly enough that there wouldn't be a problem with that, but I'll try a larger diameter hose next time.