Charlie 5320

Well-known member

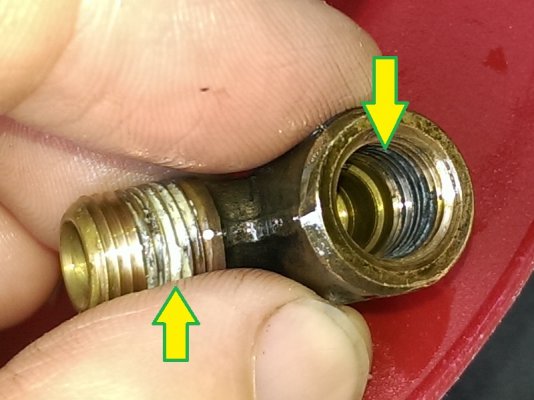

Looks like the screw was over tightened and bent. Does the float drop when you put the carb upright? If it moves under it own weight when turning the carb it's OK.

It also looks as if the screw head is touching the float body. If it is sand a flat spot on the side of the screw where it is touching.

Also take out the brass screw next to the main jet and spay cleaner through that passage.

It also looks as if the screw head is touching the float body. If it is sand a flat spot on the side of the screw where it is touching.

Also take out the brass screw next to the main jet and spay cleaner through that passage.