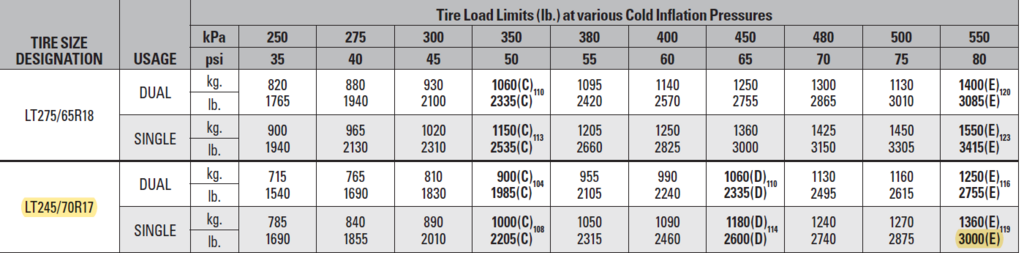

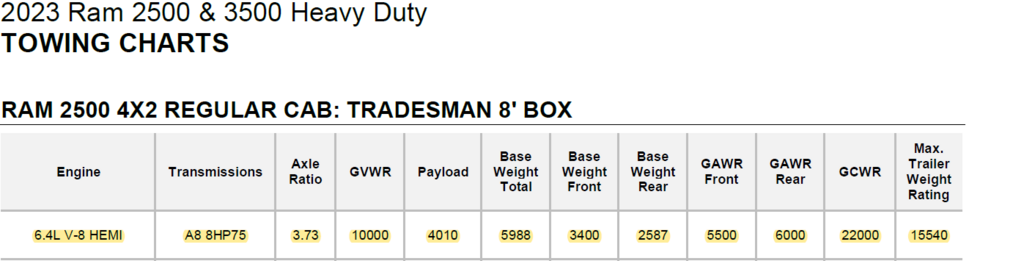

The actual Base Weight on my front is 3400, and 2600 on the rear. I have Firestone Transforce HT 245/70R17E as my OEM tires. Going by the Firestone Inflation Chart for that size tire, I should actually be running 65 in the rear and 80 in the front. But because these are the "E" rated tires, the chart shows that those parameters change to 80 for both front and back.

You are the second person I've encountered that read these charts the same, incorrect way. The other was a fellow on the Bigfoot Owners Club Forum, who insisted the same thing, because it was a load range E trailer tire then the only pressure you could use was the one with the (E) in the box.

That base weight is AXLE weight. You tires each support HALF of that weight, so a 3400lb base axle weight is 1700 PER TIRE which would be 35+ psi.

How it works is you scale the axle, and then take half of that (for one tire), and read across the chart for your ½axle/1tire weight, as determined by the scale and use the tire pressure at the top of that column (nearest higher or extrapolate). The letters (C), (D), (E) are used to denote the HIGHEST pressure (and weight) allowed for that load range tire. If your truck's rear axle, for instance, on a CAT scale, reads 4800 lbs, you would take the weight on ONE tire, 2400 lbs, and inflate that tire to 60 psi. If by chance, you had Load Range C tires instead, you would be limited to 2205 lbs and 50 psi, as that is the max for that tire, but on any Load Range tire, there is nothing keeping you from lowering the pressure at lower weights (except for your TPMS systems warning system).

The way you are reading it, there would only be three columns, 50 psi, 65 psi and 80 psi and the rest would not even exist.

These are standard charts used all across the tire industry. ANY brand of tire of that specific size and load range, is designed to carry the same weights at the same pressures, no matter the brand.

My truck, the last time I scaled it was 4060 on the front axle, thus 2030 lbs PER TIRE and I have the same size tire you have, So I should be running 45+ per tire. Dodge has 55 psi on my door placard which is based on the Gross Axle Weight Rating FRONT of 4630 which is 2315 per tire which is exactly 55 psi on the chart. My GAWR REAR is 6000, or 3000 per tire which is 80 psi. I keep the front at about 52 psi and the rear usually stays at 70 psi.

Charles