You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel Bearings

- Thread starter Bargoon

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

gwinger

Well-known member

Trailer bearings are subjected to a lot more lateral force than a car or truck. Just watch how the wheels and axles twist in opposite directions when making turns.

By repacking the bearings you may find excessive wear.

By repacking the bearings you may find excessive wear.

CharlesinGA

Well-known member

The vast majority of autos and light trucks built in the past 20 years or more, come with sealed bearings (sometimes called "unit" bearings) that you run until they fail. No way to lube them.

Older autos and light trucks used a spindle with two tapered, opposing roller bearings running in a hub, that the wheel and brake rotor or drum attaches to. This design dates back to the 1920's or earlier, with little change.

My Ford Ranger uses tapered bearings on the front, that need to be lubed, but the reality is, with a good seal, good grease, and normal operation, it doesn't get done but every 80K to 100K miles, usually when the rotor warps (it is intergral to the hub) and I replace the whole shooting match with new.

The vast majority of trailers use this same setup of two tapered roller bearings running on a spindle, with a brake drum intergral to the hub. The axle companies such as Dexter, call for re-greasing of the bearings every 12 mos or 12K miles.

Now, if you have top quality bearings (meaning it don't say CHINA on it) and you have a better than usual seal, and you used a high quality synthetic grease, hopefully with Molybdenum as an additive, then you are probably golden and do not need to lube your bearings but every two or three years or every 30k miles or so.

The frequency is in part based on the type of service. My little Ranger pickup weighs less than 3000lbs, the two front wheels carrying only 1000 or so each. They simply don't work too hard.

Now, my trailer has 3500 lb axles, meaning each spindle is rated for 1750 lbs each, and as noted above, trailer bearings "take a beating", especially side loading on tandem axles in turns, plus getting pulled over curbs and potholes that the tow vehicles seem to miss. Couple that with the fact that your trailer bearings say CHINA on them, with no hint of who actually may have made them, and a rather basic seal that may not even have a spring tensioner inside it, and you have bearings that need more frequent service.

Charles

Older autos and light trucks used a spindle with two tapered, opposing roller bearings running in a hub, that the wheel and brake rotor or drum attaches to. This design dates back to the 1920's or earlier, with little change.

My Ford Ranger uses tapered bearings on the front, that need to be lubed, but the reality is, with a good seal, good grease, and normal operation, it doesn't get done but every 80K to 100K miles, usually when the rotor warps (it is intergral to the hub) and I replace the whole shooting match with new.

The vast majority of trailers use this same setup of two tapered roller bearings running on a spindle, with a brake drum intergral to the hub. The axle companies such as Dexter, call for re-greasing of the bearings every 12 mos or 12K miles.

Now, if you have top quality bearings (meaning it don't say CHINA on it) and you have a better than usual seal, and you used a high quality synthetic grease, hopefully with Molybdenum as an additive, then you are probably golden and do not need to lube your bearings but every two or three years or every 30k miles or so.

The frequency is in part based on the type of service. My little Ranger pickup weighs less than 3000lbs, the two front wheels carrying only 1000 or so each. They simply don't work too hard.

Now, my trailer has 3500 lb axles, meaning each spindle is rated for 1750 lbs each, and as noted above, trailer bearings "take a beating", especially side loading on tandem axles in turns, plus getting pulled over curbs and potholes that the tow vehicles seem to miss. Couple that with the fact that your trailer bearings say CHINA on them, with no hint of who actually may have made them, and a rather basic seal that may not even have a spring tensioner inside it, and you have bearings that need more frequent service.

Charles

CharlesinGA

Well-known member

To add to this, few people know how to properly adjust the spindle center nut, and the bearings are left either way too loose, or preloaded tight.

Spindle nuts either are a castellation type that a cotter pin is inserted thru the slots of the nut and a hole in the spindle, or a non castellation type nut that uses a spring clip that holds the nut in place. In either case, the nut only has one of six positions it can be locked.

Now, Timken recommends that tapered, opposed wheel bearings, from the smallest trailer up to semi-trailers, have the bearings set with ZERO to 0.005" of end play. Thus NO preloading of the bearings. Previously I searched the numerous auto shop manuals I have and they all specified similar numbers. The Mercedes Sprinter shop manual even goes so far as to call out using a dial indicator to measure the end play or free play of the bearings.

I don't want to go too deep down this rabbit hole, certainly not as far as Alice went, but lets see how this ends.

The vast majority of travel trailers and utility trailers use a spindle nut that has 1"-14 thread, meaning one inch diameter and 14 threads per inch. Thus one full turn of the nut is 0.0714" of travel. If we divide this by 6 (6 flats or slots to chose from in one turn) we get 0.0119" (lets just call that 12 thousandths, 0.012")

Now, if after repeated tries and lots of careful feel of the bearings nut, we find we are almost to aligning with a slot and the hole in the spindle, we will be forced to back off to the next position, which could be eight, or nine or ten thousandths of an inch of free play, which is outside the accepted norm. Truthfully, most people will back off further than that. End result is bearings that are moving on the spindle (wearing it), and not running in the proper place on the races, but rather running on the outer edges of the races.

Dexter finally resolved this by switching to a nut with twelve slots rather than six. Much more opportunity for a careful person to get the bearing end play set within that zero to five thousandths tolerance range. (each slot position moving the nut 0.006" or "six thousandths")

I'm gonna leave the rabbit hole before I encounter the large white rabbit.............

Charles

Spindle nuts either are a castellation type that a cotter pin is inserted thru the slots of the nut and a hole in the spindle, or a non castellation type nut that uses a spring clip that holds the nut in place. In either case, the nut only has one of six positions it can be locked.

Now, Timken recommends that tapered, opposed wheel bearings, from the smallest trailer up to semi-trailers, have the bearings set with ZERO to 0.005" of end play. Thus NO preloading of the bearings. Previously I searched the numerous auto shop manuals I have and they all specified similar numbers. The Mercedes Sprinter shop manual even goes so far as to call out using a dial indicator to measure the end play or free play of the bearings.

I don't want to go too deep down this rabbit hole, certainly not as far as Alice went, but lets see how this ends.

The vast majority of travel trailers and utility trailers use a spindle nut that has 1"-14 thread, meaning one inch diameter and 14 threads per inch. Thus one full turn of the nut is 0.0714" of travel. If we divide this by 6 (6 flats or slots to chose from in one turn) we get 0.0119" (lets just call that 12 thousandths, 0.012")

Now, if after repeated tries and lots of careful feel of the bearings nut, we find we are almost to aligning with a slot and the hole in the spindle, we will be forced to back off to the next position, which could be eight, or nine or ten thousandths of an inch of free play, which is outside the accepted norm. Truthfully, most people will back off further than that. End result is bearings that are moving on the spindle (wearing it), and not running in the proper place on the races, but rather running on the outer edges of the races.

Dexter finally resolved this by switching to a nut with twelve slots rather than six. Much more opportunity for a careful person to get the bearing end play set within that zero to five thousandths tolerance range. (each slot position moving the nut 0.006" or "six thousandths")

I'm gonna leave the rabbit hole before I encounter the large white rabbit.............

Charles

Attachments

Ray-IN

Well-known member

Wow, Charles, you could write a thesis on this subject.

Mark_K5LXP

Well-known member

Both my pickup and RV have a "keeper" that fits over the castle nut offering 1/12 turn increments.

Both as well use a fairly light torque spec on the nut, then backing off to the next available increment. The bearings on my RV were toast at 55K miles, no idea when they were last serviced but I found mismatched numbers driver and passenger side, so one or the other had been replaced by a PO. The service interval is 15K miles and it's my guess that interval is determined by the bearing capacity and actual load, and I'm guessing on my RV are close to or right at max. My pickup bearings along with the brake rotors are original at 200K miles, I've repacked them several times. So the above point about the load they carry likely does make a big difference in both service life and greasing interval. I would much rather change out still-good grease and a $3 oil seal in my driveway than chase down bearings on the side of the road on a trip. It's kinda like the annual RV oil change recommendation, how some folks skip it because of few miles traveled. Oil is cheap, it's easy to do and you eliminate one variable from service/wear/failure probability.

Mark B.

Albuquerque, NM

Both as well use a fairly light torque spec on the nut, then backing off to the next available increment. The bearings on my RV were toast at 55K miles, no idea when they were last serviced but I found mismatched numbers driver and passenger side, so one or the other had been replaced by a PO. The service interval is 15K miles and it's my guess that interval is determined by the bearing capacity and actual load, and I'm guessing on my RV are close to or right at max. My pickup bearings along with the brake rotors are original at 200K miles, I've repacked them several times. So the above point about the load they carry likely does make a big difference in both service life and greasing interval. I would much rather change out still-good grease and a $3 oil seal in my driveway than chase down bearings on the side of the road on a trip. It's kinda like the annual RV oil change recommendation, how some folks skip it because of few miles traveled. Oil is cheap, it's easy to do and you eliminate one variable from service/wear/failure probability.

Mark B.

Albuquerque, NM

CharlesinGA

Well-known member

Yes, I have used those stamped retainers for years. All of my Fords use them. Not sure why Dexter didn't adopt them, to fit the plain nuts (which are used with the clips for the Ez Lube axles, which cannot be cross drilled). With those keepers you simply set the nut where you want it and keep trying the keeper till it aligns. 12 pt hex but I think it has 10 slots so you just keep trying it different ways.Both my pickup and RV have a "keeper" that fits over the castle nut offering 1/12 turn increments.

I didn't get into the exact procedure, its more of an art, to set the bearing free play by feel. I do not trust anyone else to to do my bearings.

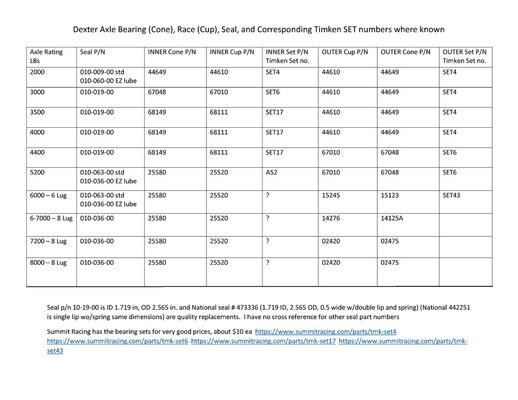

When I installed new wheels on my trailer, I went with the 6 lug version. I had to change the brake drum/hub units (brakes were the same, didn't touch them) and as the new hubs came from Dexter with CHINA races (cups) installed in them, I punched them out and chucked them in the scrap metal bucket. I installed new Timken bearing and race sets and new National seals.

Charles

Foto-n-T

Well-known member

I'm undoubtedly more neurotic about this subject than most. Our 5ver now has close to 70k miles on it since 2008 and gets the bearings pulled, inspected and repacked once a year. We've slowed our travel mileage considerably over the last few years and only get a little over 2k miles a year on the rig but I just can't skip a year because I'm paranoid and I've seen what can happen when one of those bearings fails. If you are mechanically inclined it's not too bad of a job although it's messy. I usually take two days to get it done on a triple axle rig. Whilst you're in there take a close look at your brakes as well.

Tulecreeper

Well-known member

Never repacked any on an RV. On my boat trailer, which gets towed more often than the average RV, I grease the bearings about once per quarter - or every 1200 - 1500 miles - just a few pumps, don't overdo it; and in 40 years I've owned boats I've only replaced bearings and seals maybe twice. And boat bearings are submersed regularly.I've always heard that you should repack trailer wheel bearings from time to time. I've never had to repack wheel bearings on any of my cars or trucks. So is trailer wheel bearing repacking or just a myth? Appreciate any feedback.

Replacing is an easy job, but as Foto said it can be a bit messy. One of the problems is, you really don't know what size your bearings are until you pull a wheel, disassemble everything, and look at the part number(s) on the side. At that point you already have the vehicle jacked up and the wheel off so you are kind of forced to go then and get bearings and seals unless you want your trailer up on jacks for an extended period.

Rene T

Site Team

Master Chief, which boat bearings are submerged regularly?. And boat bearings are submersed regularly.

Tulecreeper

Well-known member

Keep your day job.Master Chief, which boat bearings are submerged regularly?I had to.

submerse: verb - put under water; verb - sink below the surface; go under or as if under water; synonym: submerge

It's just Chief, not Master Chief (although we just call each other Chief, or Bob

John From Detroit

Well-known member

I'm undoubtedly more neurotic about this subject than most. Our 5ver now has close to 70k miles on it since 2008 and gets the bearings pulled, inspected and repacked once a year. We've slowed our travel mileage considerably over the last few years and only get a little over 2k miles a year on the rig but I just can't skip a year because I'm paranoid and I've seen what can happen when one of those bearings fails. If you are mechanically inclined it's not too bad of a job although it's messy. I usually take two days to get it done on a triple axle rig. Whilst you're in there take a close look at your brakes as well.

That is not being paranoid. That is protecting your asset (The 5ER)

Isaac-1

Well-known member

I find it interesting how people can retire after 20-30 years of military service, then work in a completely different field for another 20-30 and retire from that job. I have an uncle who just turned 90 a few months ago, who spent 20 years in the Air Force retired as a full colonel (he was an electronic warfare officer on B52's during Vietnam), then went on to work for another 20 years as the head janitor at a high school in rural Washington state, retired from that then moved back home to Louisiana about 25 years ago. Between which after getting out of the Air Force he and his first wife (who passed away about 30 years ago), bought a Class A Pace Arrow motorhome and traveled the US for 2 or 3 years before settling in central Washington state.

I retired from the Coast Guard after 22 1/2 years , worked there as a Chief Machinery Technician. Then 14 years driving a semi and now have 12 years working for my son doing landscaping. Plus a lot of camping.I find it interesting how people can retire after 20-30 years of military service, then work in a completely different field for another 20-30 and retire from that job. I have an uncle who just turned 90 a few months ago, who spent 20 years in the Air Force retired as a full colonel (he was an electronic warfare officer on B52's during Vietnam), then went on to work for another 20 years as the head janitor at a high school in rural Washington state, retired from that then moved back home to Louisiana about 25 years ago. Between which after getting out of the Air Force he and his first wife (who passed away about 30 years ago), bought a Class A Pace Arrow motorhome and traveled the US for 2 or 3 years before settling in central Washington state.

Tulecreeper

Well-known member

I find it interesting how people can retire after 20-30 years of military service, then work in a completely different field for another 20-30 and retire from that job. I have an uncle who just turned 90 a few months ago, who spent 20 years in the Air Force retired as a full colonel (he was an electronic warfare officer on B52's during Vietnam), then went on to work for another 20 years as the head janitor at a high school in rural Washington state, retired from that then moved back home to Louisiana about 25 years ago. Between which after getting out of the Air Force he and his first wife (who passed away about 30 years ago), bought a Class A Pace Arrow motorhome and traveled the US for 2 or 3 years before settling in central Washington state.

I did 3 years Navy Active Duty from 1980 - 1983, then got out and had to do 2 obligated years in the Reserves. When that time was up, I re-enlisted - again and again, until I had 25+ years in. In the meantime, I went to work for a Sheriff's Office for 7 years, then went to another Sheriff's Office for 2 years, then went to work for Fish & Wildlife and stayed there for 20+ years.I retired from the Coast Guard after 22 1/2 years , worked there as a Chief Machinery Technician. Then 14 years driving a semi and now have 12 years working for my son doing landscaping. Plus a lot of camping.

Also in the meantime, I got recalled to Active Duty in 1991 for 6 months during Desert Storm (not everyone was lucky and came home in Feb 1991). And recalled again in 2001 for a year after 9-1-1. Both times sent to the sandbox (Middle East). And recalled again a second time in 2004 sent back to the sandbox.

So, I did my military and LE things kind of simultaneously.

I've had a lot of people ask me, "Why would the Navy send anyone to the desert?" Well, I was attached to an anti-terrorism/force protection unit and there was need for special security during a lot of the operations going on over there. We provided that security.

markandkim

Well-known member

Wheel bearings

We do ours regularly. Not sure if the tyre problem we had last year was the tyres or the wheel bearings as the guy told us they were all shot, despite the fact they should have been done by the RV guys less than a year before. I suspect they hadn't done them.

Ray-IN

Well-known member

I cannot remember what vehicle I was working on, but the book said after the normal spin-tighten thing to torque the wheel bearings to 40 lb/ft then back off to the first cotter pin notch. I was never comfortable doing that; I could visualize flat spots on bearings and dents in races.

Bargoon, Dexter axle says to repack wheel bearings every 12 mos. or 12,000 miles, even their EZ-lube axles.

Bargoon, Dexter axle says to repack wheel bearings every 12 mos. or 12,000 miles, even their EZ-lube axles.

Rene T

Site Team

Those parts are harder than woodpecker lips. They won’t dent. I usually just tighten the nut while rotating the wheel just to make sure the balls have seated without any interference from grease. Then I back off the nut to the 1st cotter pin holeI cannot remember what vehicle I was working on, but the book said after the normal spin-tighten thing to torque the wheel bearings to 40 lb/ft then back off to the first cotter pin notch. I was never comfortable doing that; I could visualize flat spots on bearings and dents in races.

Bargoon, Dexter axle says to repack wheel bearings every 12 mos. or 12,000 miles, even their EZ-lube axles.

Ray-IN

Well-known member

Don't you mean rollers?Those parts are harder than woodpecker lips. They won’t dent. I usually just tighten the nut while rotating the wheel just to make sure the balls have seated without any interference from grease. Then I back off the nut to the 1st cotter pin hole