You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Generator starts, runs, then dies

- Thread starter MGH

- Start date

The friendliest place on the web for anyone with an RV or an interest in RVing!

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Tulecreeper

Well-known member

A mild hum is normal. If it's buzzing, it's not happy.

Lou Schneider

Site Team

- Joined

- Mar 14, 2005

- Posts

- 13,344

1800 or 3600 RPM, it's normal for the voltage to increase if the speed is high, decrease if the speed is low.

I finally have some significant progress and will say that this is mostly resolved!

When I started back at this a couple weeks ago, I found that my Kill-A-Watt meter was dead. Not sure how that happened, as I’d only ever used it for troubleshooting this one issue. But I figured, “That’s okay, I already set the engine rpm back in May…”

But now, up against another impasse, and remembering the 347 times I’ve read on this forum, “Get yourself a Kill-A-Watt meter”, I decided I better get a new one and make sure we’re still okay on the rpm front. Nope. The generator was running, but producing 120VAC at 79 Hz

I had monkeyed with the rpm before, trying to get the VAC into range. Today I adjusted it down to produce ~60.5 Hz +/- 0.5. The voltage stayed constant at 120 VAC. And functionally everything is working MUCH better, as below:

Today I didn’t try running with the oil pressure switch connected at any time. I will try tomorrow. Not sure if that’s an independent issue, or also related to the mess above.

Thanks again to everyone for offering thoughts, advice, and diagnostic assistance!

When I started back at this a couple weeks ago, I found that my Kill-A-Watt meter was dead. Not sure how that happened, as I’d only ever used it for troubleshooting this one issue. But I figured, “That’s okay, I already set the engine rpm back in May…”

But now, up against another impasse, and remembering the 347 times I’ve read on this forum, “Get yourself a Kill-A-Watt meter”, I decided I better get a new one and make sure we’re still okay on the rpm front. Nope. The generator was running, but producing 120VAC at 79 Hz

I had monkeyed with the rpm before, trying to get the VAC into range. Today I adjusted it down to produce ~60.5 Hz +/- 0.5. The voltage stayed constant at 120 VAC. And functionally everything is working MUCH better, as below:

- Still have the oil pressure switch disconnected.

- Started and ran just fine.

- Adjusted rpm down to produce ~60.5 Hz +/- 0.5. Generator continued to run throughout.

- Turned on A/C, with compressor, after just a couple minutes of running.

- Allowed generator and A/C to run for 30 minutes.

- Turned A/C off, then back on, and it ran without interrupting the VAC power.

- Previously the generator would continue to run, but VAC power would shut off and the transfer switch would buzz until turning off the generator.

- Let A/C run another 10 minutes, turned off, turned back on. All good.

- Turned A/C off, then shut down generator using the stop switch at the generator.

- Started generator again after just ~10 seconds, ran and kept running and producing 120VAC at 60 Hz just fine.

- Previously I would not be able to re-start the generator while still hot.

Today I didn’t try running with the oil pressure switch connected at any time. I will try tomorrow. Not sure if that’s an independent issue, or also related to the mess above.

Thanks again to everyone for offering thoughts, advice, and diagnostic assistance!

RedForeman

Well-known member

I've been following this a while out of curiosity to see where it goes. I do not own an RV yet, so definitely not one of these Onan gensets. But I do have some remarks that might be worth some consideration.

Two or three careers ago, I was occupied as an automotive mechanic for about 10 years. I specialized in electrical and driveability. My usual job was second or third hand, after other shops had attempted and failed. One thing always held true: the more complicated a problem seemed, the more simple the repair was.

This was usually because the previous tech inadvertently had made incorrect assumptions. The best example being grounds. You look at one and it appears clean. Or at least just a little road dirt on it. Maybe tug on it, and it seems solid. But did you remove it and actually inspect it closely? It probably needed to be cleaned up anyway, but who has time for that?

Then I come along and do that. Find out the terminal is against a painted surface. Or has green cancer inside the terminal, etc. I'm not saying OP has not been thorough. What I am saying, however, is don't assume anything, especially the simple stuff that is foundational for everything else.

I'll wrap up this novel with a fun story. My previous big truck had a Thermo King Tripac APU. This is a small 2 cyl diesel engine mounted on the frame, and supplies a/c and alternator to the truck when parked for driver comfort during a break, and also circulates it's coolant with the truck engine to serve as a preheat in cold weather.

Anywho, along the way this apu began randomly stalling, but would immediately restart. It might run hours, days, or even weeks between stall events. I travel with a dog, so often would have to idle the truck when going inside for food or shower instead of trusting the apu not to die. Time to really dig in was limited, and it ran most of the time so troubleshooting was catch as catch can.

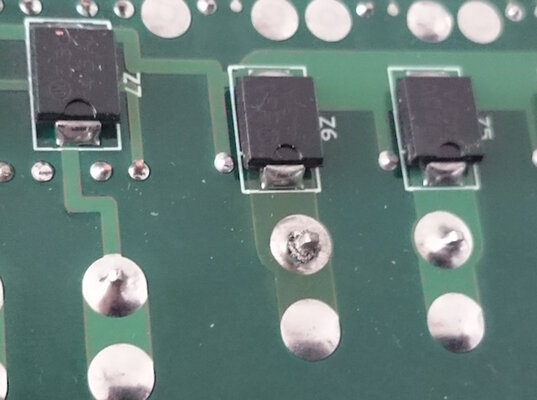

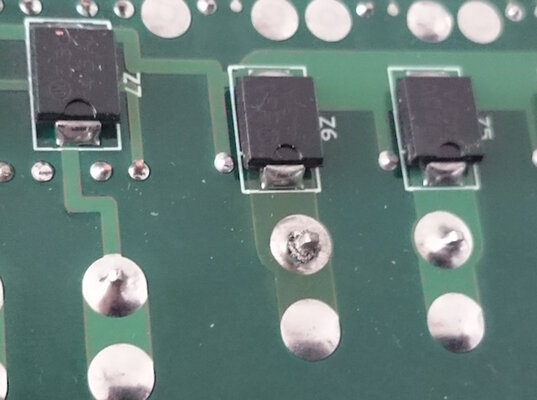

This persisted over two years! Over that time I replaced many cable terminals, relays, oil and coolant switches, you name it. On one particularly productive day I was poking around on the control board and I got it to stall on purpose by pressing on one of the relays. Swapping it around didn't matter, and being about fed up with it anyway, decided it must be the control board itself. I found a used one on eBay for a good price and swapped it out for the win.

Upon removing the old one, I discovered what had been the cause of all that drama. One cold solder joint on the back of the board, that serves the run relay. Pressing on that spot would flex the board and open the circuit, causing the engine to die.

Two or three careers ago, I was occupied as an automotive mechanic for about 10 years. I specialized in electrical and driveability. My usual job was second or third hand, after other shops had attempted and failed. One thing always held true: the more complicated a problem seemed, the more simple the repair was.

This was usually because the previous tech inadvertently had made incorrect assumptions. The best example being grounds. You look at one and it appears clean. Or at least just a little road dirt on it. Maybe tug on it, and it seems solid. But did you remove it and actually inspect it closely? It probably needed to be cleaned up anyway, but who has time for that?

Then I come along and do that. Find out the terminal is against a painted surface. Or has green cancer inside the terminal, etc. I'm not saying OP has not been thorough. What I am saying, however, is don't assume anything, especially the simple stuff that is foundational for everything else.

I'll wrap up this novel with a fun story. My previous big truck had a Thermo King Tripac APU. This is a small 2 cyl diesel engine mounted on the frame, and supplies a/c and alternator to the truck when parked for driver comfort during a break, and also circulates it's coolant with the truck engine to serve as a preheat in cold weather.

Anywho, along the way this apu began randomly stalling, but would immediately restart. It might run hours, days, or even weeks between stall events. I travel with a dog, so often would have to idle the truck when going inside for food or shower instead of trusting the apu not to die. Time to really dig in was limited, and it ran most of the time so troubleshooting was catch as catch can.

This persisted over two years! Over that time I replaced many cable terminals, relays, oil and coolant switches, you name it. On one particularly productive day I was poking around on the control board and I got it to stall on purpose by pressing on one of the relays. Swapping it around didn't matter, and being about fed up with it anyway, decided it must be the control board itself. I found a used one on eBay for a good price and swapped it out for the win.

Upon removing the old one, I discovered what had been the cause of all that drama. One cold solder joint on the back of the board, that serves the run relay. Pressing on that spot would flex the board and open the circuit, causing the engine to die.

Old_Crow

Well-known member

At one point in the '90's, when I was still working at the Chevy dealership, we were changing the circuit boards on the wiper motors by the bushel full. Got so bad it turned into a recall. Anyway, one of my co-workers got to fussing with one of the old boards and discovered that the problem was cold solder joints where the connector was attached to the board. We started re-soldering these joints for certain customers and never had a repeat failure on one of the repaired boards.

I love a good root cause determination. Not kidding. I had a manager that used to say, "There's always a reason...". It sticks with me, there is.Upon removing the old one, I discovered what had been the cause of all that drama. One cold solder joint on the back of the board, that serves the run relay. Pressing on that spot would flex the board and open the circuit, causing the engine to die.

It may take a while, but I hope someday I'll fully understand what's been going on with this generator. In the meantime, and as it stands now, here's today's update:

- Connected the oil pressure switch.

- Started okay, but died after a few seconds.

- Started again okay, but died after a few seconds again.

- Disconnected oil pressure switch.

- Started and fine, producing 120VAC at 60 Hz.

- Ran one A/C for ~30 minutes.

- Added the other A/C and ran both for another 30 minutes.

- Shut off A/C units, then generator, manually.

- Restarted generator while hot, and it ran again okay.

John From Detroit

Well-known member

Well you diagnosed it or limited it to one of two things.. One more diagnosis step.

The Suspect list:

Low oil pressure

Bad oil pressure switch

The final test

Remove switch replace with oil pressure gauge. Run genny. Good pressure Replace gauge with a NEW switch. Bad pressure ... OUCH (Major overhaul)

The Suspect list:

Low oil pressure

Bad oil pressure switch

The final test

Remove switch replace with oil pressure gauge. Run genny. Good pressure Replace gauge with a NEW switch. Bad pressure ... OUCH (Major overhaul)