Hi,

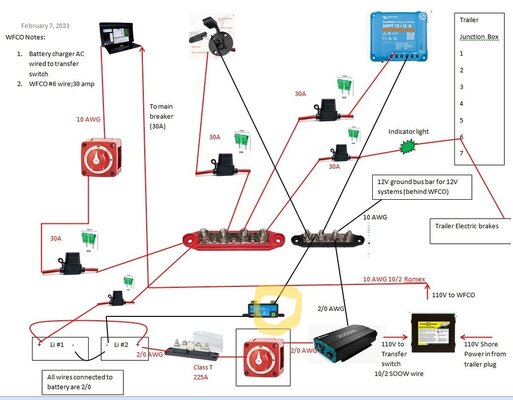

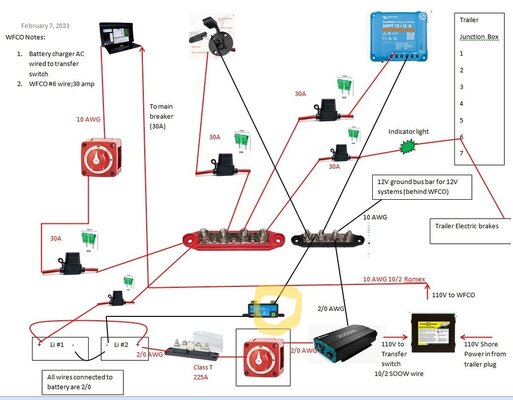

I have a small camper with an inverter set up. Below is my diagram.

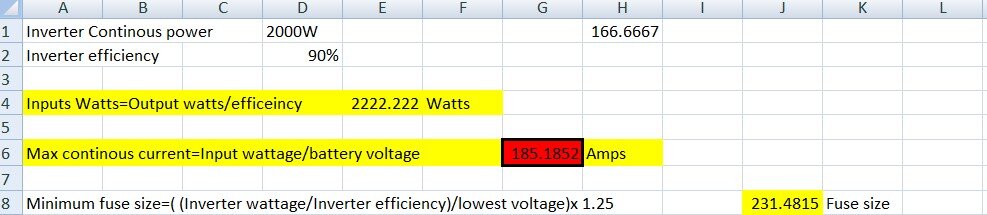

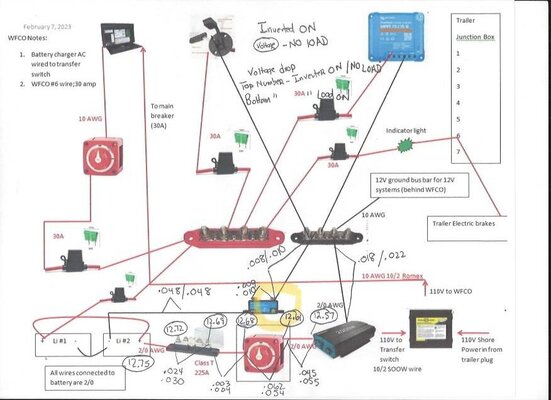

To check for heat build up in connections and wires, I placed a cup of water in the microwave and ran it for 5 minutes under battery and inverter power.

All of the connections (including the T-Fuse) stayed cool with maybe a 2- 4F increase except for 1 (circled in yellow). The load side of my shunt raised about 40F with the 2/0 wire getting warm to the touch with about a 40F increase in temp. I used an infrared temp. gun to measure. This connection point is a 2/0 wire going to the busbar.

I checked for the obvious loose connection, but it seems tight.

Do I need to be concerned? Any suggestions ?

Thank you

I have a small camper with an inverter set up. Below is my diagram.

To check for heat build up in connections and wires, I placed a cup of water in the microwave and ran it for 5 minutes under battery and inverter power.

All of the connections (including the T-Fuse) stayed cool with maybe a 2- 4F increase except for 1 (circled in yellow). The load side of my shunt raised about 40F with the 2/0 wire getting warm to the touch with about a 40F increase in temp. I used an infrared temp. gun to measure. This connection point is a 2/0 wire going to the busbar.

I checked for the obvious loose connection, but it seems tight.

Do I need to be concerned? Any suggestions ?

Thank you