Gregg,

That pretty well sums it up.

Now that you have bled the fluid out of the jacks, you'll surely have to add more before they will go down again. And, if you ran the pump after bleeding the jacks, chances are there is air in the lines and they'll have to be bled just like you would do with brake lines. Start at the one farthest from the pump reservoir and work your way closer in. You'll have to keep adding fluid to the reservoir when doing that, and once you're done, you'll have to retract the jacks to push out any excess fluid. It's going to be messy, but necessary. Have lots of paper towels (and beer) close at hand.

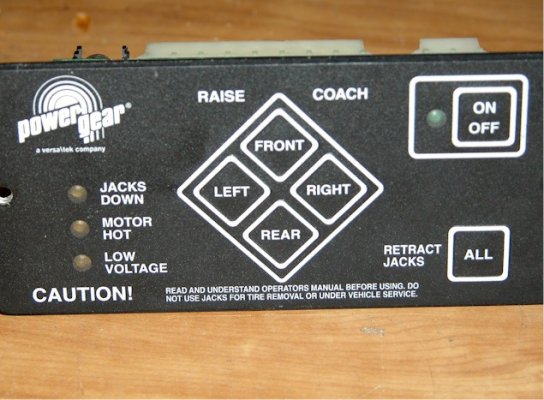

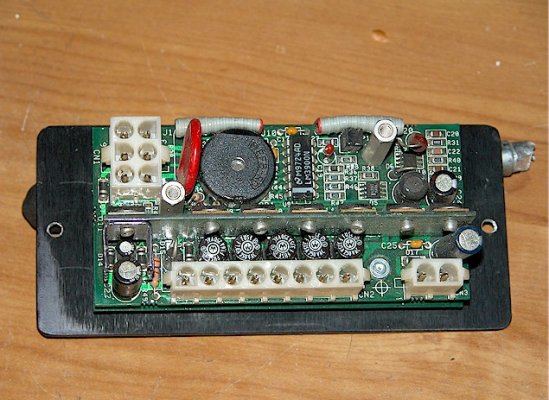

If you have the same control board like the one in the pictures, be aware that there are fuses mounted on it too. Locate the large, 10-pin white connector. That connector goes directly to the various solenoids. Directly above it, you'll see 5 round, black objects. Those are the fuses that protect the control board if a solenoid or wiring to them should become shorted. However, as John mentioned about the solenoids, it's unlikely that multiples of them would have blown and are the cause of your problem. If all else fails, check the three white connectors. They lock in place so, again, it's unlikely to be your problem, but something to keep in mind.

but my jacks will not retract. I can turn them on I can raise them. I also do not show a light for jacks down. The power vendors user amnual I have reccomended checking a fuse behing the operator panel..I did...it was OK. Any thoughts folks?

but my jacks will not retract. I can turn them on I can raise them. I also do not show a light for jacks down. The power vendors user amnual I have reccomended checking a fuse behing the operator panel..I did...it was OK. Any thoughts folks?