I would use nothing less than 18 gauge and preferably 16 gauge. This is for durability of the wire, and yes, having enough wire to terminate at the 12v fuse panel. Are these screw terminals where the wire goes under a "pinch" plate that the screw holds down?

If the wire is not run in an existing bundle, I use split wire loom material to protect it. I buy 1/4 inch split loom sleeve in a box of 50 ft from NAPA, good quality stuff. If running in an existing bundle I make sure it is clamped and tied properly.

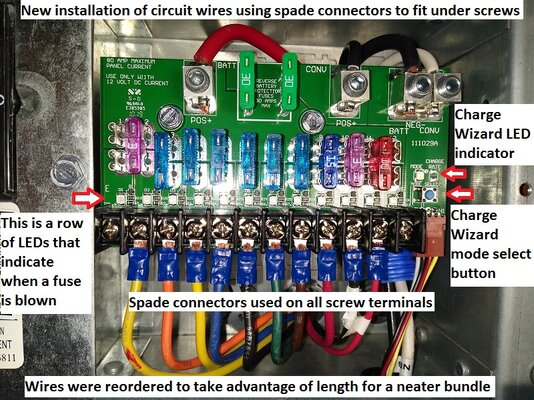

Depending on the terminals, use either U terminal ends or buy a ferrule kit and do it that way. I have re-terminated all of the wires on my 12v DC fuse panel and on my ground bar also.

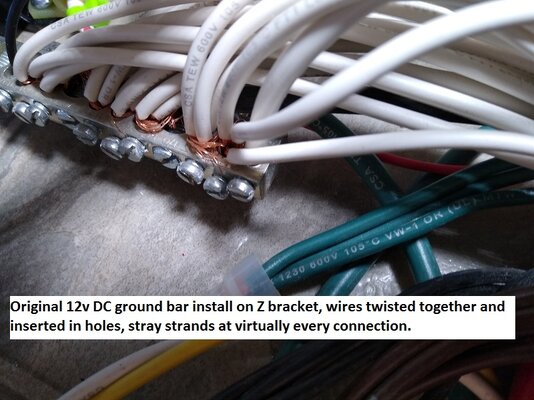

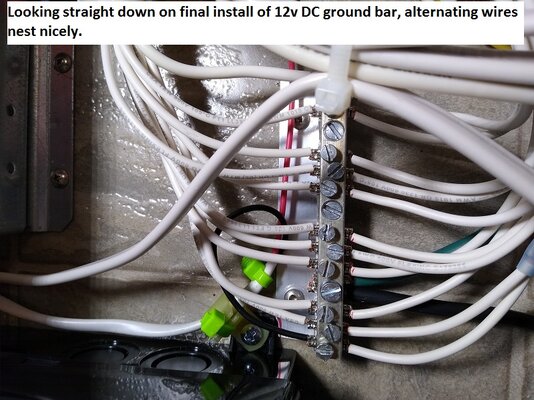

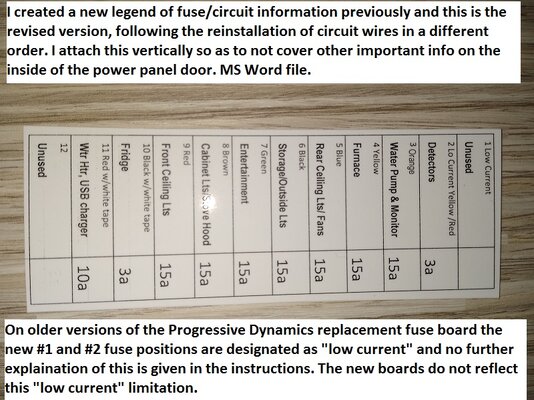

Pics tell the story. White ground wires jammed into the ground bar, loose and flayed strands. Installed ferrules, then staggered the wires in the terminals after remounting the ground bar. Previously I installed a new fuse panel and just inserted the wires under the retainer plates. When I pulled it apart, I found flayed wire strands. All wires were terminated with U spade terminals that FIT the space in the terminal under the retainer plate.

Note that I did not use the ferrules with insulated sleeves, as I needed longer ones. I ordered several sizes from Ferrules Direct. The crimpers and box of insulated sleeves came from Amazon.

Charles