Frank B

Well-known member

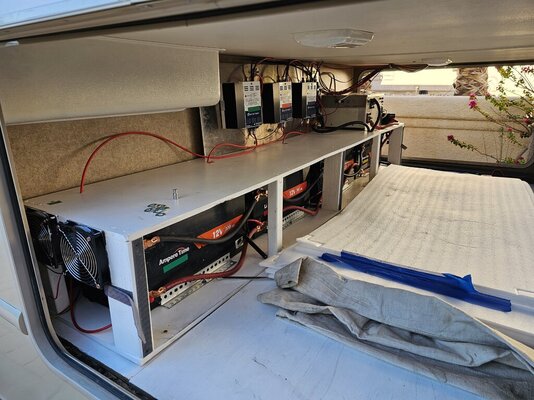

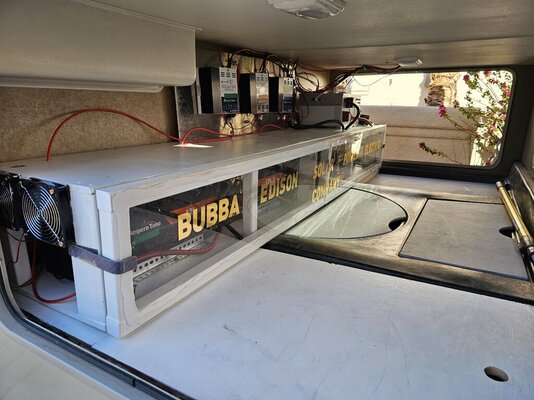

I spent most of the night working on the Bubba Edison Version 2.0 replqcement AC power generating system.

Years ago when I replaced the Norcold refer with a residential model in my DP, I saved the Stainless Steel door inserts thinking I might use them someday for something.

Tonight I found a use for one of them.

I mounted three of the four charge controllers, input and output DC circuit breakers, and the shunt for the battery monitor on the stainless steel panel.

Solarman, has mentioned the advantage of mounting on metal for heat dispersion.

The other controller is the Master controller and these three are networked as slave controllers.

The Master controller is recessed into the wall in the bedroom like before with the battery monitor next to it.

It will hang this equipment panel with a J channel on the wall of the rear storage compartment above the four batteries.

Without pictures...well you know the rest.

Love the big rubber 'persuader' on the R side of the bench. They make everything fit so much better.