View attachment 169044

Not a happy camper. There was something about using a grinder to clean the pipes. Something about having to smooth out adhesive so things don’t get stuck there.

Many

jokes.

And this: “why couldn’t it have been the grey tank?”.

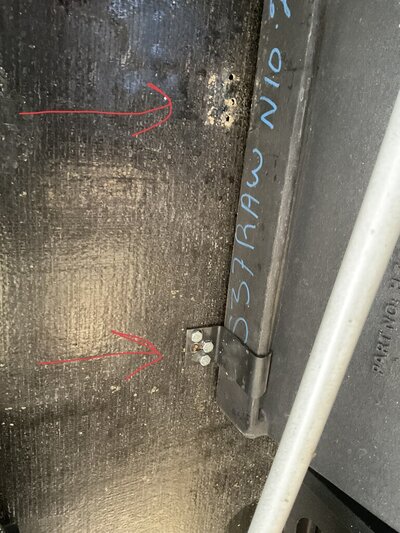

The hefty brackets arrived and will go on tomorrow. The marine adhesive needs to cure 24 hours. He’s Not sure if any strapping will work because the only place to attach is the underside of the plywood floor which is where the brackets attach. He got meatier screws too.

Apparently the repair went very well. “Textbook” he said. He also said “it should be better than when it came off the line.”

We plan to test it by filling it up (with water and ice to clean it) and taking it down our lane.